Forklifts are essential equipment in factories and warehouses for heavy industrial lifting, stacking, and transport. The demands for forklifts will only continue to rise as the demands for flexible manufacturing and faster goods-to-person fulfillment soar in the face of the pandemic.

Forklift operation, however, is no cheap endeavor for a business, with operating costs outweighing the vehicle price and maintenance costs. A forklift operator is paid at an average of $50k per shift per year, with each forklift being used by two to three operators around the clock. In having human drivers in warehouse logistics, there are also costs related to misplaced inventory. The average inventory inaccuracy rate is 1.25%, which translates to that much financial loss.

But cost isn’t the only issue with manned forklift operation. Driving a forklift strains the driver and exposes the driver to various hazards. According to Occupational Safety and Health Administration (OSHA), around 85 fatal and 34,900 serious forklift-related accidents occur in the U.S. every year.

There are several options. But cost isn’t the only issue with manned forklift operation. Driving a forklift strains the driver and exposes the driver to various hazards. According to Occupational Safety and Health Administration (OSHA), around 85 fatal and 34,900 serious forklift-related accidents occur in the U.S. every year.

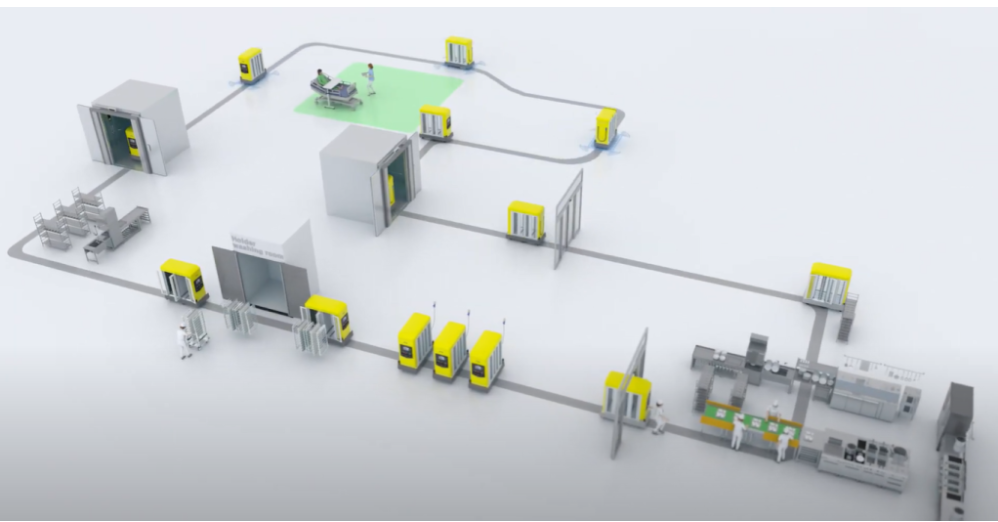

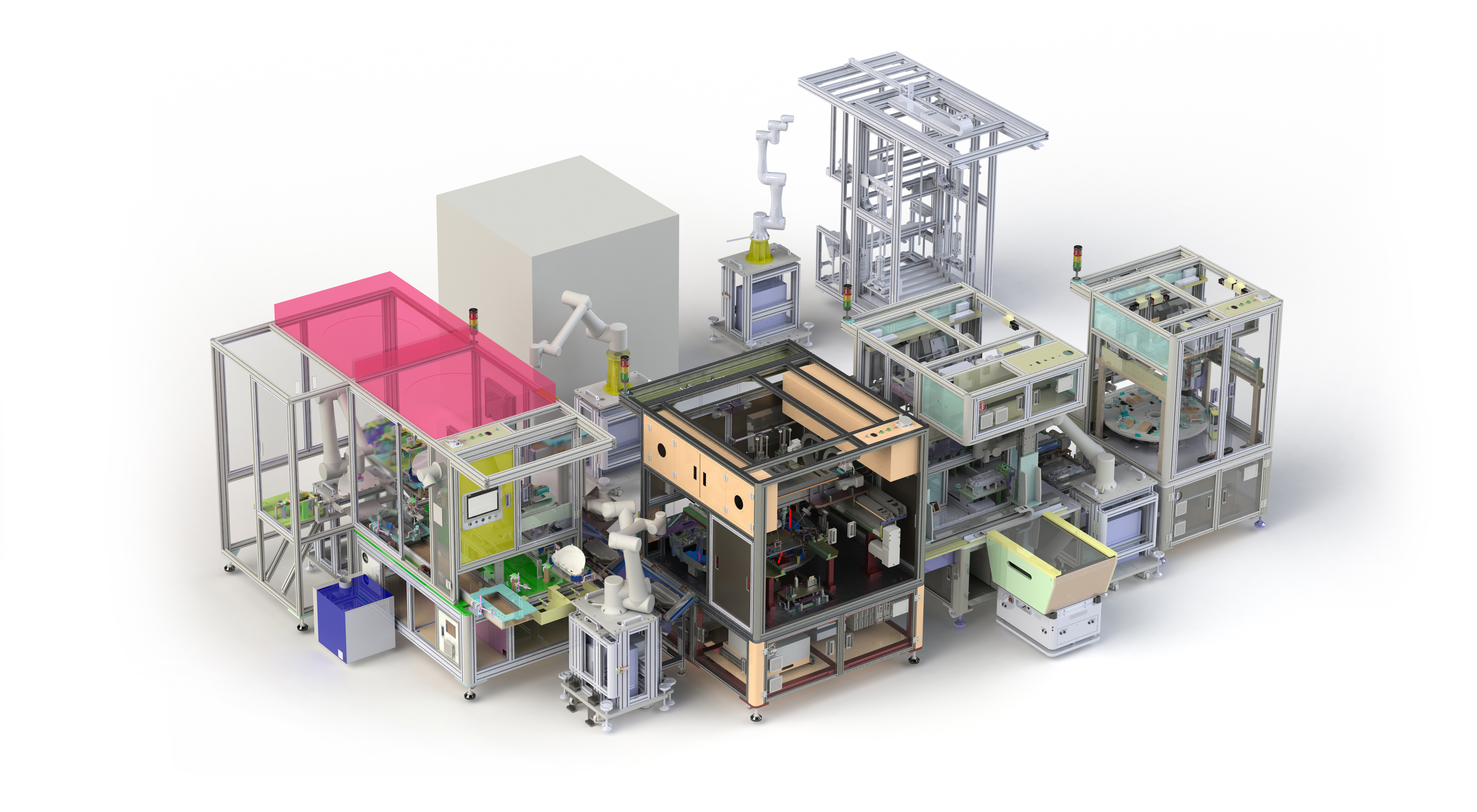

From where it stands, turning forklifts autonomous would reduce the cost of operation, improve safety, and leave little room for human error. Equipping forklifts with autonomy is crucial to automating and optimizing various logistics processes, especially at loading and unloading points. Unlike mobile platforms that need top modules for simple loading and unloading operations, forklifts can move heavy-duty loads horizontally as well as vertically and even stack loads in racks. Whereas endowing full autonomous mobility on outdoor automobiles is an extremely challenging problem, factories and warehouses are closed indoor environments with relatively predictable elements, a close-to-ideal real world closed systems for reliable self-driving forklifts. Furthermore, the tasks usually required of forklifts are highly standardized and repetitive, rendering them perfect candidates for automation.

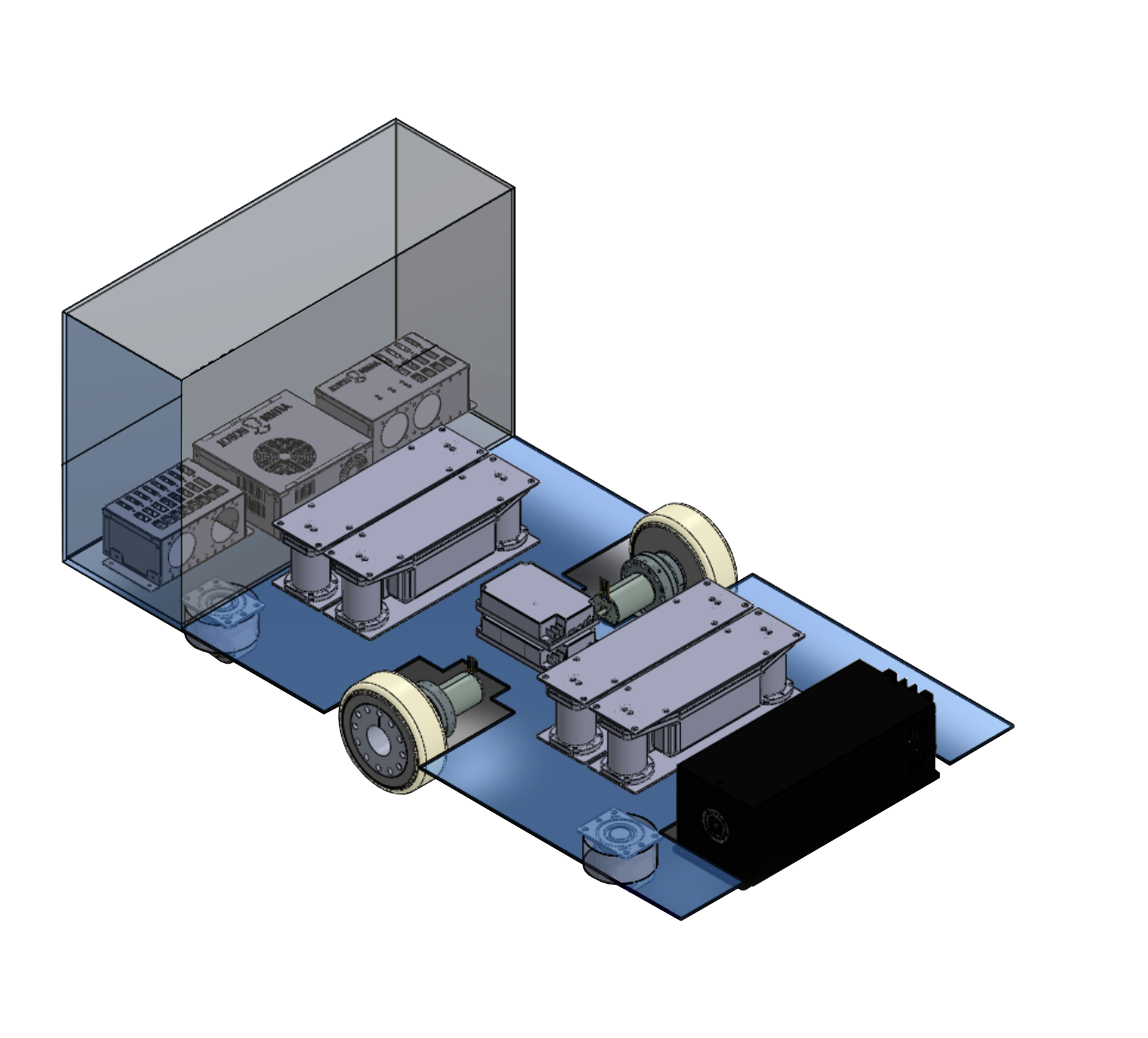

Automating existing manual forklifts are achieved by equipping them with SLAM, navigation, and functional safety software as well as necessary sensor attachments and hardware modifications. Warehouses do not need to dispose of their existing models in order to incorporate autonomous forklifts. With the aid of AI, forklifts can also make semantic sense of their surroundings, making them smarter.

Yujin Robot offers client-fitted robotization solution to transform manual forklifts to autonomous forklifts with its proprietary product lines, including LiDAR, SLAM-Navigation, and fleet management system (FMS).