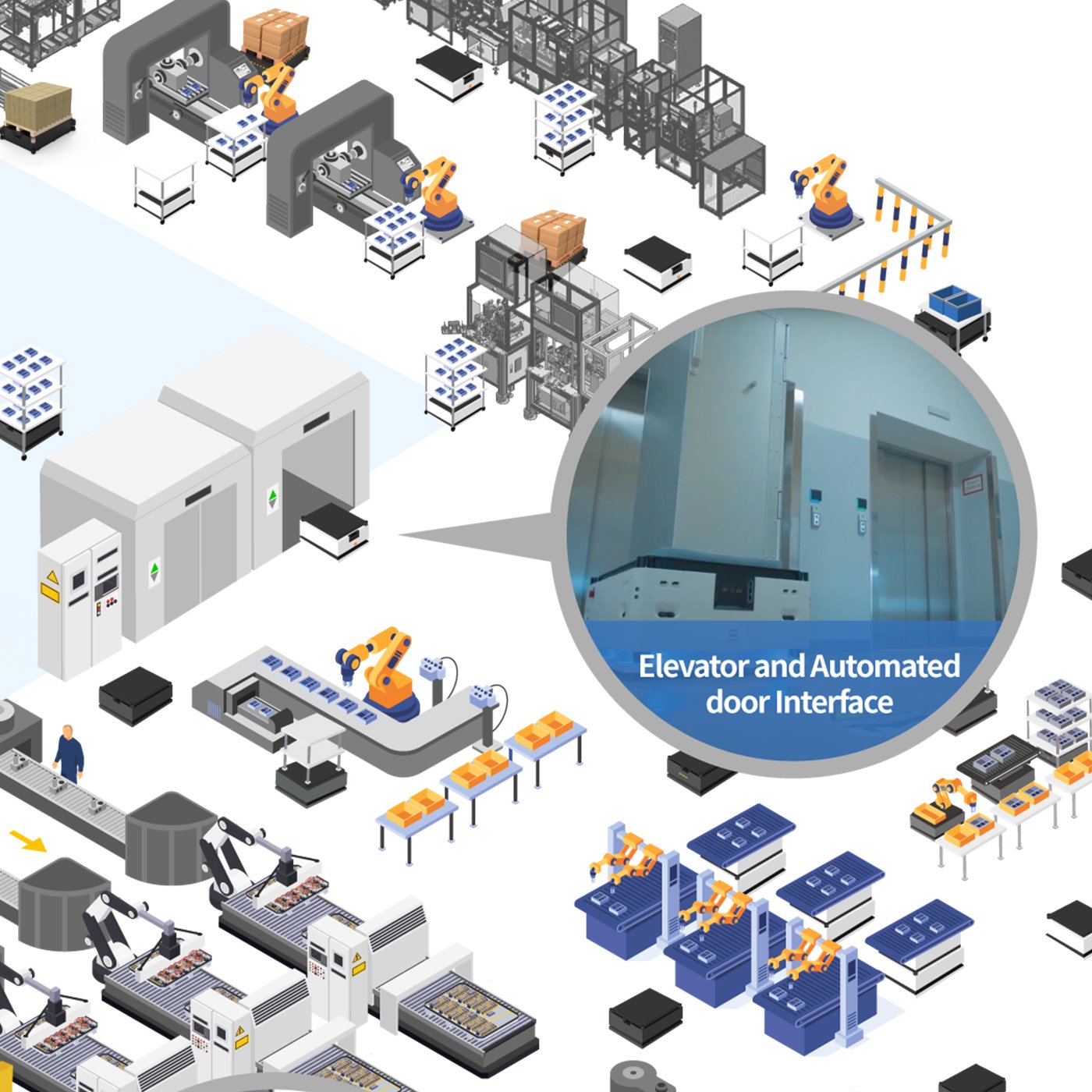

GoCart can be interfaced with various on-board devices, elevators, and automatic doors.

Discover the success stories of Yujin Robot Solutions in a variety of industrial sites

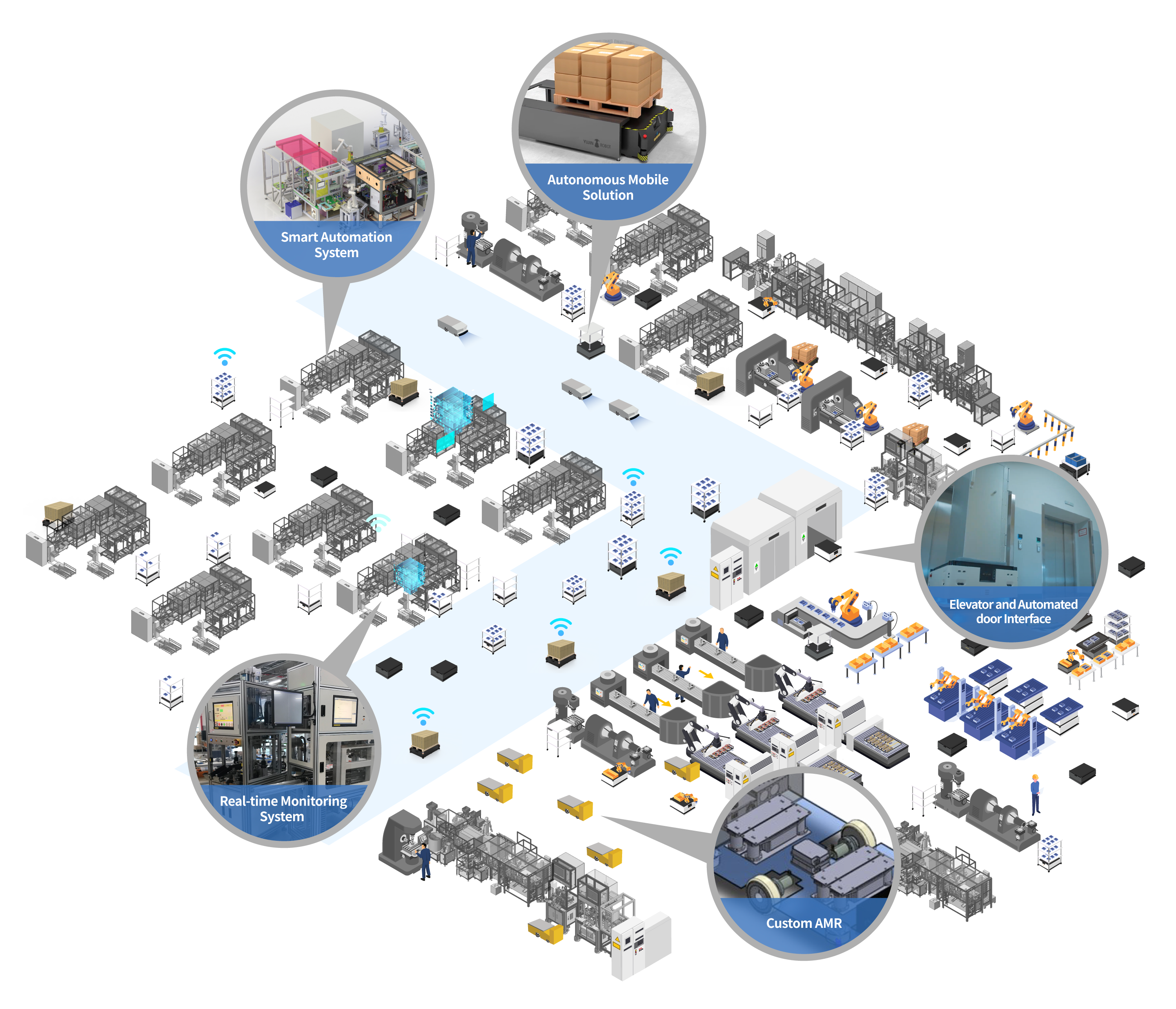

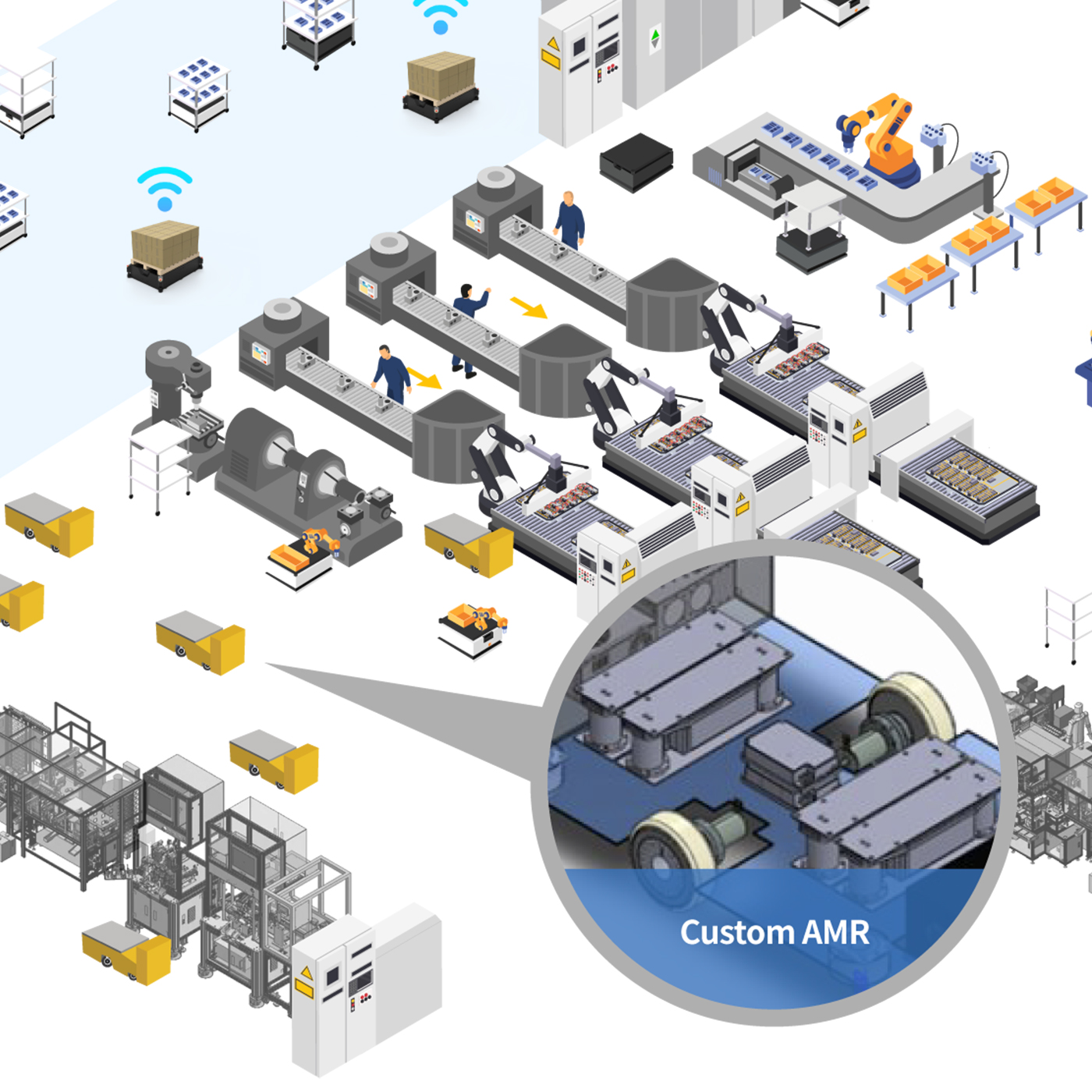

Yujin Robot is applying logistics automation and factory automation based on autonomous mobility technology to various areas from industrial sites to daily life. Based on the technology of the first-generation robot company in Korea, we have independently developed SLAM, Navigation, and 3D LiDAR, which are robot construction units, and through the autonomous driving mobile platform GoCart, we complete logistics automation and factory automation systems that increase production efficiency and provide customer satisfaction value through end-to-end robotics solutions in factories, warehouses, and hospitals.

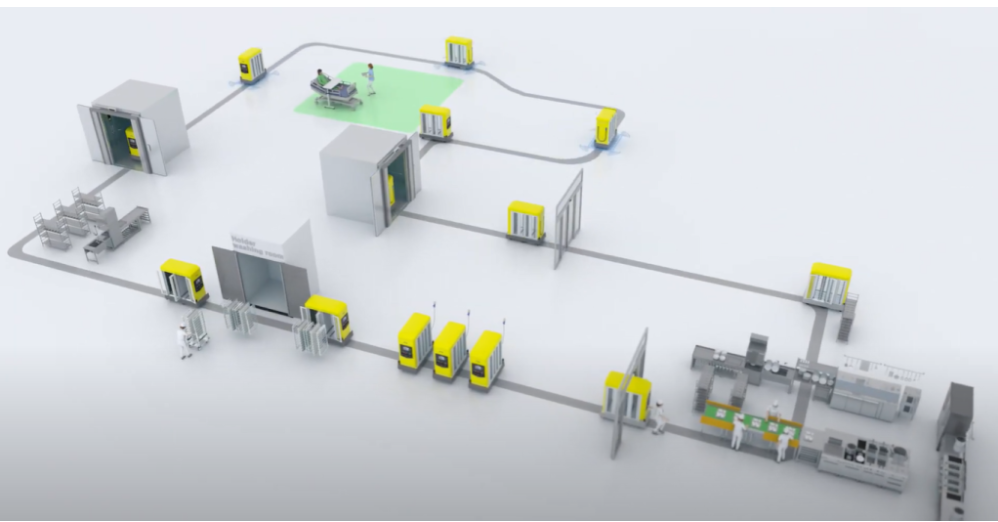

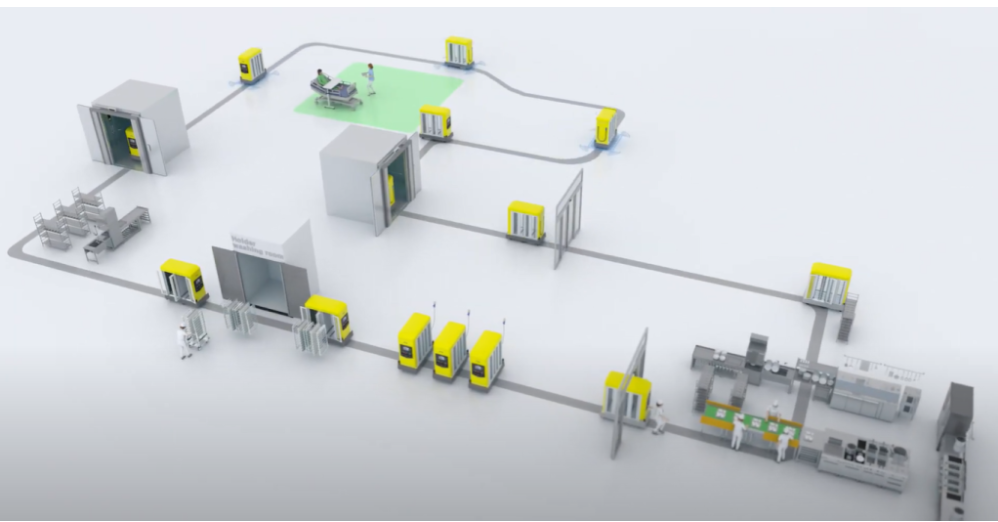

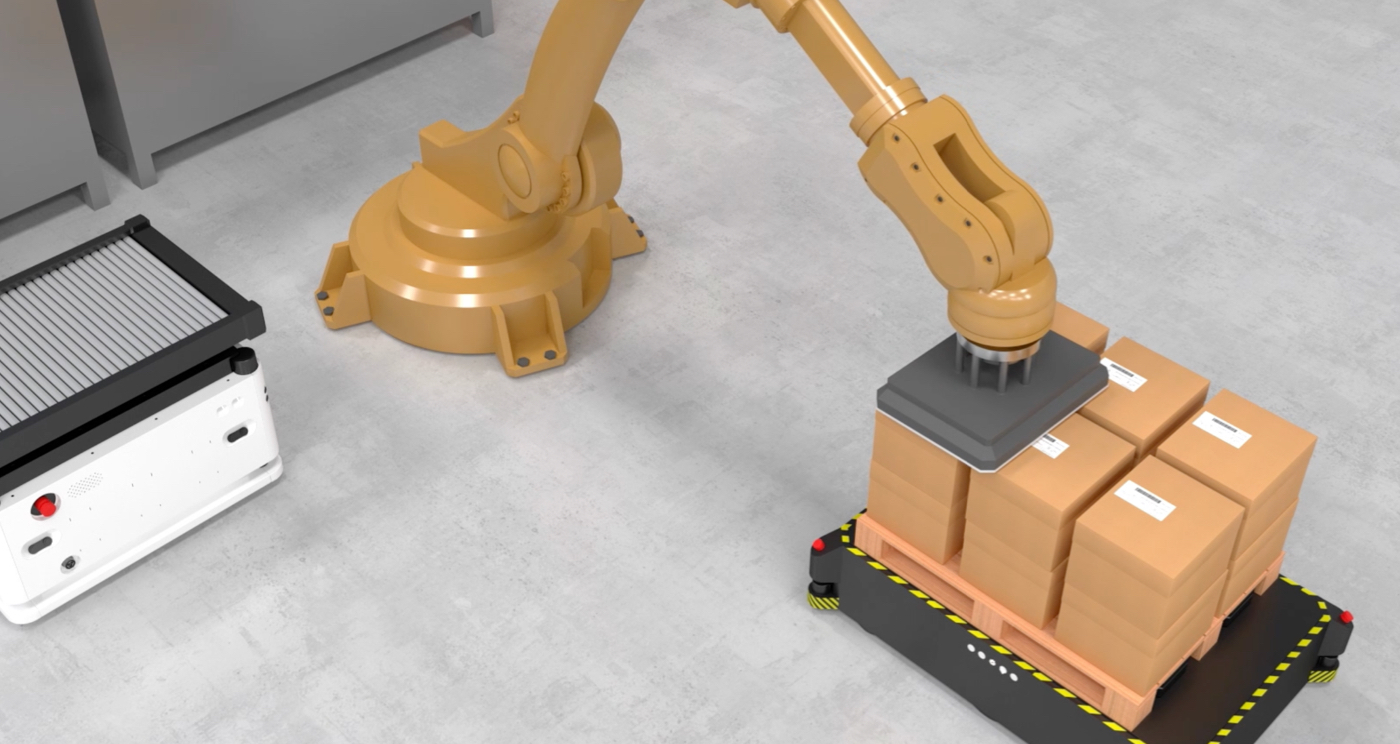

In line with the trends such as unmanned vehicles and the acceleration of the logistics industry, which are spreading in line with the 4th industrial era, Yujin Robot completes the factory logistics automation system by incorporating its own AMR and GoCart into the field where logistics transfer frequently occurs. It boasts optimal productivity according to various in-site processes, ensures safety, and maximizes efficiency by minimizing unnecessary manpower.

Logistics Automation Solutions

Reduced on-the-job errors, ensuring fast and safe productivity

Prevention of worker injuries and completion of a pleasant working environment

Unnecessary cost and efficient staffing

더 많은 사례보기

GoCart

Transport

Manufacture

Logistics Automation

Robot

Transport

Assembly Automation

Logistics Automation

Robot

Transport

Check out more information about our AMR products for healthcare, factory and warehouse applications

Check out the videos of our application in our YouTube channel

Product brochure is available for download.

Standard AMR

Max. Payload: 180 kg

Operating Speed: 1.0 m/s

Loading Surface Dimension (L x W): Max. 646 x 441 mm (25.43" x 17.36")

Driving Method: Differential

Max. Payload: 250 kg

Operating Speed: 1.0 m/s

Loading Surface Dimension (L x W): Max. 840 x 640 mm (33.07" X 25.19")

Driving Method: Differential

Max. Payload: 500 kg

Operating Speed: 1.0 m/s

Loading Surface Dimension (L x W): Max. 1222 x 822 mm (43.30" x 30.31")

Driving Method: Differential

Max. Payload: 1000 / 1500 kg

Operating Speed: 1.0 m/s

Loading Surface Dimension (L x W): Max. 1222 x 822 mm (48.11" X 32.36")

Driving Method: Differential

-2.png)

Max. Payload: 200 kg

Operating Speed: 1.0 m/s

Loading Surface Dimension (L x W): Max. 897 x 697 mm (35.31" x 26.73")

Driving Method: Omni Directional