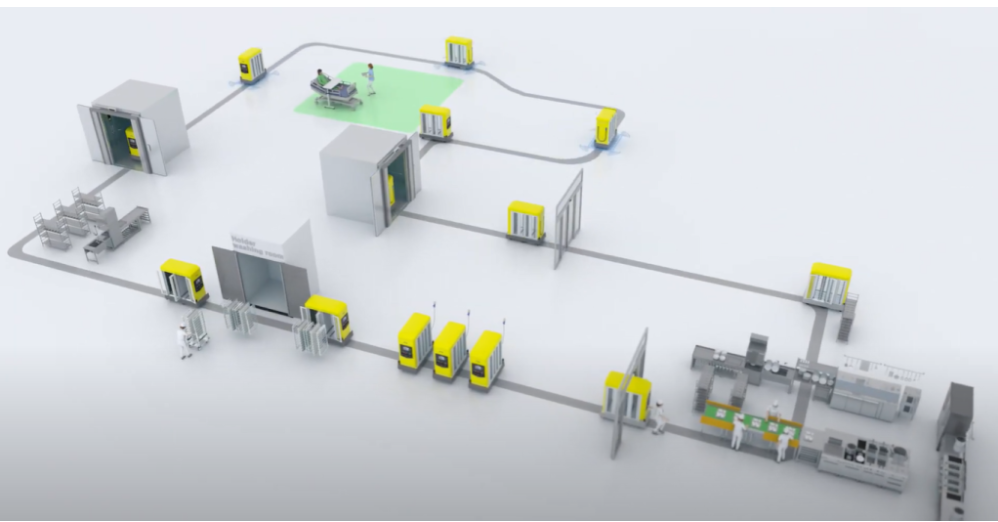

Rapid advances in technology, including AI and machine learning, have led to record numbers of autonomous mobile robots (AMRs) in factories and warehouses worldwide. Workers have benefited in safety and productivity as robots take on repetetive and dangerous tasks, freeing humans for more complex and creative roles. Robots on the job also lead to fewer mistakes and accidents.

Along with the many benefits of robots across industries like manufacturing and health care, there are challenges that leaders need to consider when it comes to implementing AMRs in the workplace.

This blog post will cover the impact of employing robots on worker and facility safety and operations. We’ll also touch on safety regulations around robots that every decision-maker should know before launching an AMR program.

The Safety Advantages of AMRs

There are a number of safety advantages that come as a result of adding AMRs into your workplace.

- Improved worker safety. AMRs are designed to take on repetitive, strenuous or hazardous tasks. This minimizes the risk to human workers and frees them to perform higher-level jobs.

- Error reduction. When workers are fatigued, injured or stretched thin, errors are bound to happen. AMRs can perform tasks with precision and predictability. This consistency mitigates lapses that can lead to injuries.

- Minimized infection risk. AMRs can perform cleaning or collection tasks in areas that would be hazardous to humans, such as hospital infectious disease wards.

GoCart AMR Improves Efficiency & Safety for Korean Warehouse

Safety Considerations for AMR Integration

Before adding AMRs to your facility, it’s important to think about the safety of your employees and anyone else who may come into contact with robots while on the job. We’ve included a helpful checklist at the end of this post to guide you through the AMR integration process.

Human worker safety. Unlike fixed industrial robots, AMRs work among humans without a fence or barrier in between. Staff need to be trained to work alongside robots, and robots should have a clear path to perform their tasks.

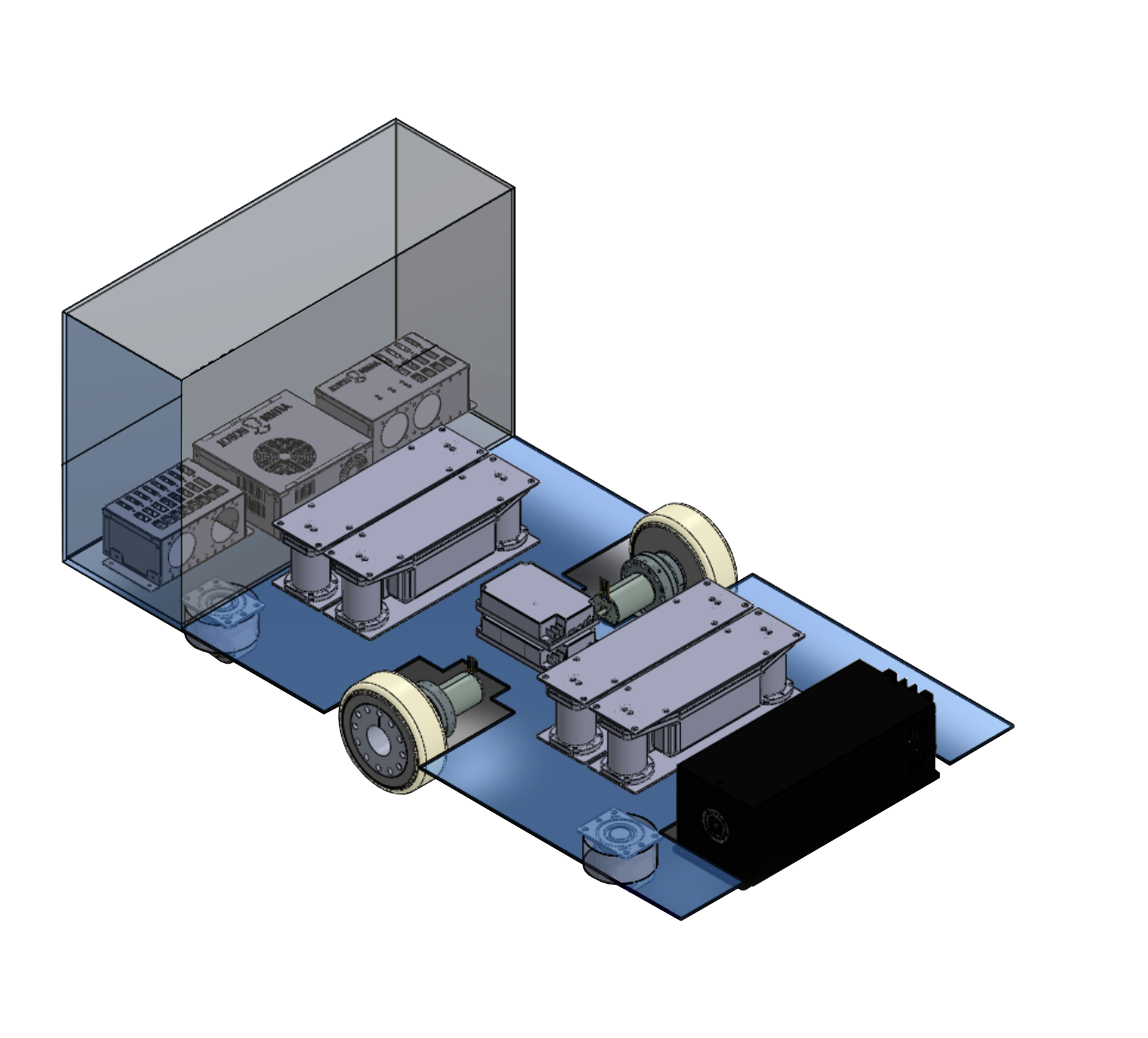

Sensor safety measure. Any robots you bring into the workplace need to be equipped with safety sensors or a redundant safety system to control algorithmic object detection and avoidance. They should have rules to adapt their speed and course when confronted with an object or person and come with safety speed limits and stop functions. This is known as functional safety (FuSa), or the idea that people should be protected from technology.

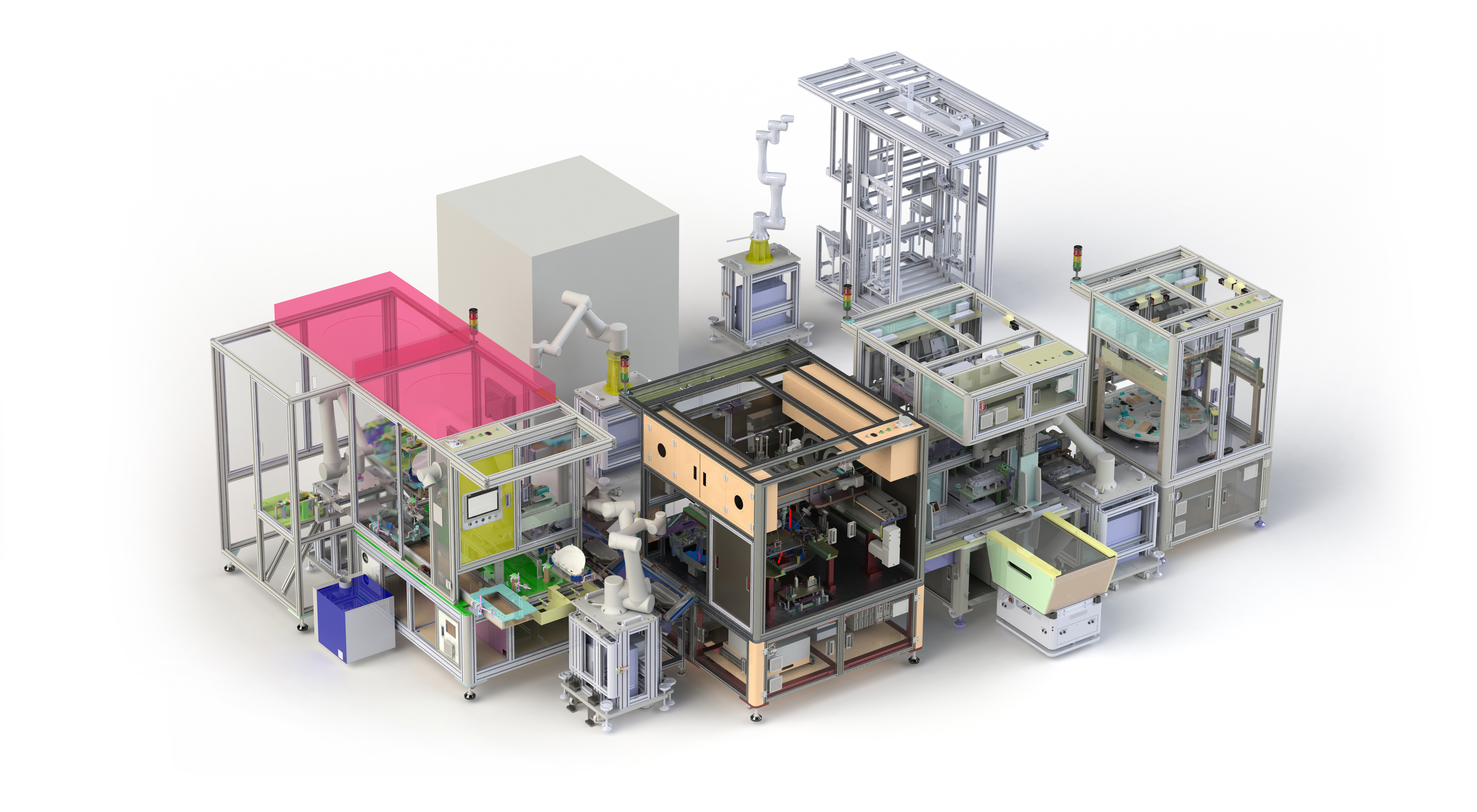

Facility considerations. Facilities come in all shapes and sizes. Some may be more accommodating to AMRs than others. Conduct a facility assessment to map out tight corners or potential bottlenecks. Also, take into consideration the width of corridors to allow for AMR navigation and how AMRs will operate with other mobile machines such as forklifts.

Understanding Regulations: U.S. and International

The ANSI/RIA R15.08 standard for industrial mobile robots (IMR), which includes AMRs, lays out specific standards for their use. The American standards were developed by manufacturers, integrators, end users and component suppliers over four years and rolled out in three parts beginning in 2020.

The first part includes minimum requirements for safe operation, including:

- What the robot can detect and see

- How far and high the robot can see

- How quickly it needs to stop

- The signals and indicators required

- Allowed travel speeds

The second part of ANSI/RIA R15.08, released in the fall of 2023, governs the risk assessment and safety standards for integrating and deploying mobile robots. The third part will focus on end-users, including those configuring and managing AMRs.

While ANSI is the standard for North American robot safety, the International Organization for Standardization (ISO) has also developed different sets of evolving guidelines. ISO 3691-4 was revised in 2023 and covers safety requirements and verification for driverless industrial trucks, including autonomous mobile robots. The standards cover risk assessment and safety measures across all phases of the life of an AMR. ISO 13482 lays out standards for personal care robot safety.

Neither ANSI nor ISO standards are mandates, but adhering to these guidelines shows a commitment to best practices in a rapidly evolving field. By following guidelines, manufacturers and end users ensure safety for those working with and alongside AMRs and mitigate the risk of accidents in the workplace.

AMR Integration Checklist

AMRs are highly flexible and adaptable to a wide variety of industries and environments. But as with any change within your organization, it’s important to prepare.

Before Implementation

- Determine your need for AMRs. Which areas would benefit from automation without disrupting your current operations?

- Conduct a risk assessment to identify potential hazards related to robots in your facility and among your human workforce. What impact will AMRs have on your operations and workforce?

- Analyze your facility’s physical space, including floor condition, floor plan, wifi connectivity and lighting. Are there any areas that could be challenging for AMRs to navigate or hazardous to humans interacting with them?

- Conduct employee training designed to familiarize your staff with AMRs. They should understand what to expect and feel comfortable handling and interacting with them as needed.

- Conduct a budget analysis to ensure maximum ROI for your AMR integration.

Selecting Your AMR

- Work with an AMR supplier to choose the robot model that best fits your needs. Yujin Robot’s GoCart can be customized to suit your facility and payload requirements.

- Make sure the AMR you choose complies with the latest safety standards.

- Ensure your AMR supplier can also provide system integration solutions that work with your existing equipment and software systems.

Implementation and Ongoing Support

- Set up and program your robot with the help of your AMR supplier.

- Set up protocols for maintenance, updates and troubleshooting.

- Create systems for monitoring and data collection to ensure smooth operations and ongoing improvement.

- Gather feedback from staff to gauge how the robot is performing and where there is room for improvement.

Adding AMRs With Care

Implementing AMRs into your facility can be a game-changer for productivity, efficiency and safety. However, to get the maximum benefit from AMRs, it’s important to approach their integration with care and due diligence. Adopting a proactive strategy for safety and compliance will ensure your AMR program succeeds.