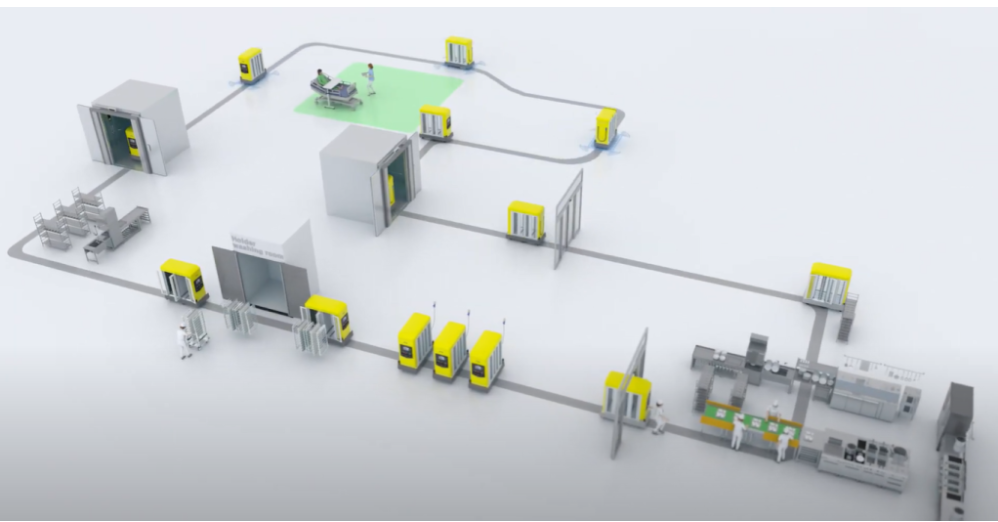

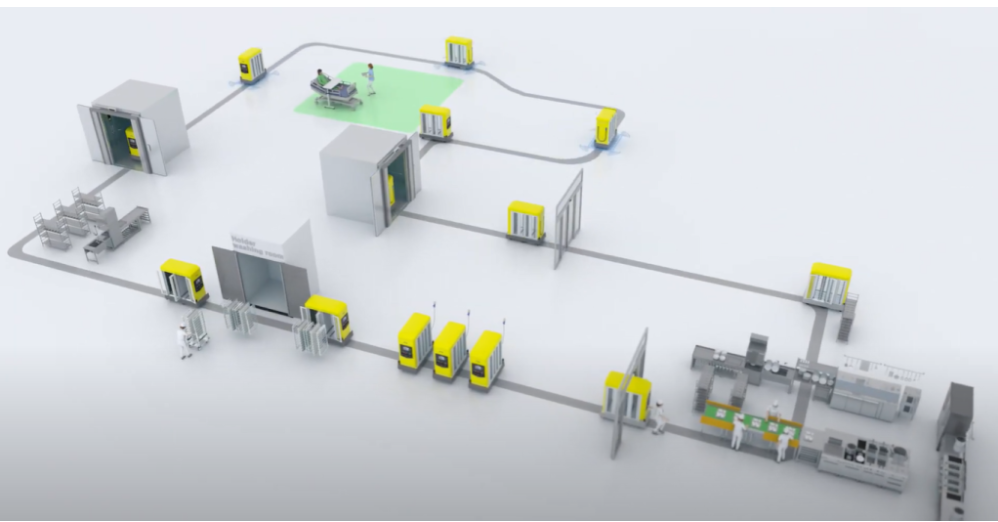

Autonomous mobile robots (AMRs) have revolutionized how we approach the logistics, manufacturing and service industries. As the technology that powers AMRs continues to develop, AMRs are able to take on increasingly complex tasks and transport heavier loads.

As automation becomes more prevalent in every industry, from factories and warehouses to hospitals, understanding payload in robotics — the maximum weight or load capacity that can be handled by the robotic system or automated machines — becomes critical for managers and decision-makers. This article will explore:

How evolving capabilities and increased payloads are reshaping the way AMRs are used ROI, challenges and considerations when implementing AMRs in existing environments Requirements for implementing AMR in facilities

AMR Market Trends: Increased Payload

The trend in AMRs across industries and applications is clear: Businesses want robots that can transport more weight. Robotics manufacturers are not shying away from the challenge.

Amazon recently introduced Titan, its internal warehouse AMR that can carry up to 1,122.9 kilograms (2,500 pounds), doubling the payload capacity of its previous model. And Yujin Robot’s Heavy Payload AMR can carry up to 2,000 kilograms (4,400 pounds).

As payload capabilities increase, AMR applications also change. AMRs can now transport pallets and handle more complex tasks related to materials/inventory transport. This transition reflects the growing versatility of AMRs and their ability to adapt to more varied operational needs in different sectors, especially warehouse logistics and manufacturing.

Maximizing the ROI of AMRs in Your Facility

Higher payload offers versatility, but it comes with additional costs for high-capacity motors, mechanical parts, superstructure equipment such as lifts and conveyors and operational costs.

A small AMR with a low payload and limited capabilities may cost as little as $30,000, while a more sophisticated AMR with a higher payload can cost two to three times that amount.

Your ultimate ROI will be determined by a number of factors, including the upfront cost of the AMR, how much it will cost to integrate it into your current facility and the annual maintenance cost.

The vendor you work with can help you identify how to save money by implementing an AMR, which means some of those costs can be offset by future savings. This includes freeing up human workers to perform other tasks and reducing injuries.

Payload and ROI

Higher-payload AMRs can result in a higher ROI, but only if the robot’s specs are in line with your needs and environmental considerations. The right payload capacity ensures optimal productivity and more efficient cycle times.

Safety. Every workplace wants to keep both its employees and equipment safe. Selecting the AMR with the proper payload capacity is the first step in preventing equipment damage and ensuring safety for the employees, but it’s also important to educate workers about the importance of payloads in robotics.

When everyone in the work environment understands and respects payload capacity, it reduces the likelihood of overloaded robots — and that means it also helps prevent accidents, product damage, equipment failure and injuries to employees.

Efficiency. Of course, one of the main features of automation is that it creates a more efficient workplace. When managers know the payload capacity of their robotic equipment, they can maximize the use of robots while never exceeding the designated load-bearing limits. (It also means they won’t have too light of a payload, either, which could be inefficient and waste time on the floor.)

This helps optimize workflows and ensures that each piece of equipment is being used to its greatest capacity every time. And when that happens, it means greater productivity and less downtime for employees.

Equipment longevity. As already mentioned, overloading equipment can result in equipment failure. And even if it doesn’t reach the point of failure, repeatedly overloading equipment will result in it showing signs of wear and tear much faster. That means more frequent breakdowns — resulting in decreased productivity — and increased maintenance and repairs.

As with all major purchases for a company, it’s important to understand what kinds of costs you’re able to support. If you’re considering adding a robot to your manufacturing floor, it’s important to determine what you’re able to spend and whether the robot will offer the expected return on your initial investment.

Environmental Constraints

As AMR payloads increase, so does the overall footprint. This can cause issues if you’re trying to integrate AMRs into existing smaller spaces. Before placing larger AMRs in your facility, you need to consider the following environmental factors:

Facility, corridor size and layout

Any doors, corridors or elevators that may be difficult for a larger AMR to navigate

Traffic in and around the AMR’s work zone, including co-operation of other manned equipment such as forklifts.

Heavier payloads and larger sizes also add safety considerations. It is crucial that AMRs can safely work alongside human employees. Before implementing high-payload AMRs, make sure you understand the robot’s navigation capabilities, collision avoidance systems and ability to respond to unexpected obstacles in the environment. Selecting an AMR which has industry-accredited safety certifications such as ISO13482 PL-d rating may be an important factor to consider especially if you have an environment with heavy employee traffic in your manufacturing or warehousing facility.

Requirements for Adopting AMRs

The final determination of which payload in robotics to adopt has to be carefully planned, taking into account the environmental factors mentioned above as well as safety issues, cycle time, TAKT time, and transport material type, size and weight.

What Is TAKT Time?

TAKT time is a metric used in manufacturing to dictate the rate of production required to meet customer demand. If you think of it as an equation, you can calculate TAKT time by dividing the total available production time by the number of items customers require over that period.

For example, if a customer needs 100 units per day and there are 800 minutes of production time available, the TAKT time would be 8 minutes per unit.

TAKT time is important when planning for AMRs in your facility because it helps you determine the number of robots you’ll need and how fast you need them to work.

Using TAKT Time to Determine AMR Capacity

When determining the requirements for using AMRs in your facility, consider the following:

How much space can you give an AMR? Look at factors like your floor space and the size of doorways, corridors and elevators to determine the largest footprint AMR possible for your facility.

What is the maximum payload that needs to be transported? Evaluate the items you haul now — trays, boxes, pallets, trolleys, etc. What is the maximum weight you’ll need an AMR to transport?

How long does it take your current equipment to do the job? Think about the time it takes from start to finish (cycle time) for your current staff or equipment to do any task that may be assisted or replaced by AMRs.

After you’ve answered the above questions, calculate the highest TAKT time — remember, that’s the maximum time it takes to finish the work divided by customer demand. This number will help you determine both the number and type of AMRs you’ll need.

Finding the Right Vendor

Once you have an idea of what type of AMR you’ll require and are talking to vendors, they can help explain what robots they have that provide a good fit for your environment. The right vendor can address any specialized needs in your factory or warehouse and may be able to propose the most adequate AMR to support those needs.

As robots become part of the modern workplace, finding AMR solutions that suit your exact needs is imperative to integrating them into your operations successfully. Choosing the right equipment begins with understanding what you need and finding the right vendor to introduce you to the robot that checks all the other boxes, too.

Next Steps: How to Calculate Payload

When working with a vendor, you want to make sure its AMRs will fit into your processes. Following these steps can help clarify what type of robot you’re looking for and what type of payload you require:

1. Identify parameters. One of the first steps in determining what kind of payload you require is to pinpoint what specific tasks it needs to perform. This also means identifying what materials and products it will handle. Just as with interviewing human candidates, identifying the specifics of its on-the-job duties helps determine which robot is best suited for the job.

2. Determine the weight of products. After you’ve identified what materials need to be lifted and transported, calculate the weight of the heaviest items or components that will be handled. These calculations will provide some of the primary considerations for the necessary payload capacity.

3. Calculate potential payload changes. Are there any occasional temporary increases or variations in the weight of your products? These should always be factored in; based on those possible spikes, you’ll want to establish guidelines to ensure payloads are always within the specified limits.

4. Analyze your production volume. By understanding the daily or hourly production volume, you can determine how quickly the automated equipment needs to be able to move products through the system to keep operations running smoothly.

5. Consider your company’s future expansion. Because a robot is a long-term investment that will be part of your operations for years to come, it’s important to consider any possible plans for changes or additions in your product line that could potentially change payload requirements down the road.

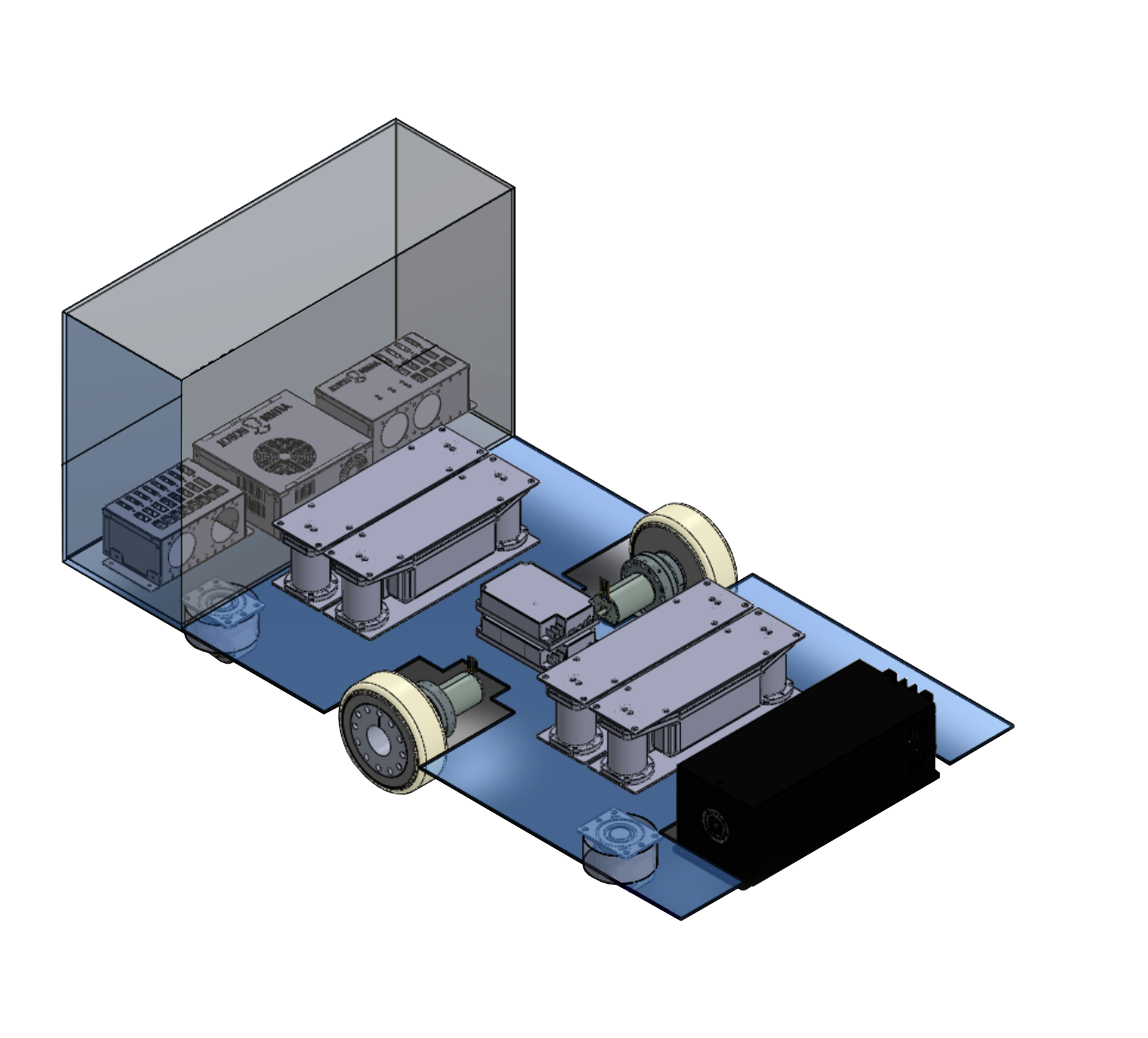

Specification Yujin Robot's autonomous solution applied to the dispensing cart

Robot

Specification Yujin Robot's autonomous solution applied to the dispensing cart

Robot

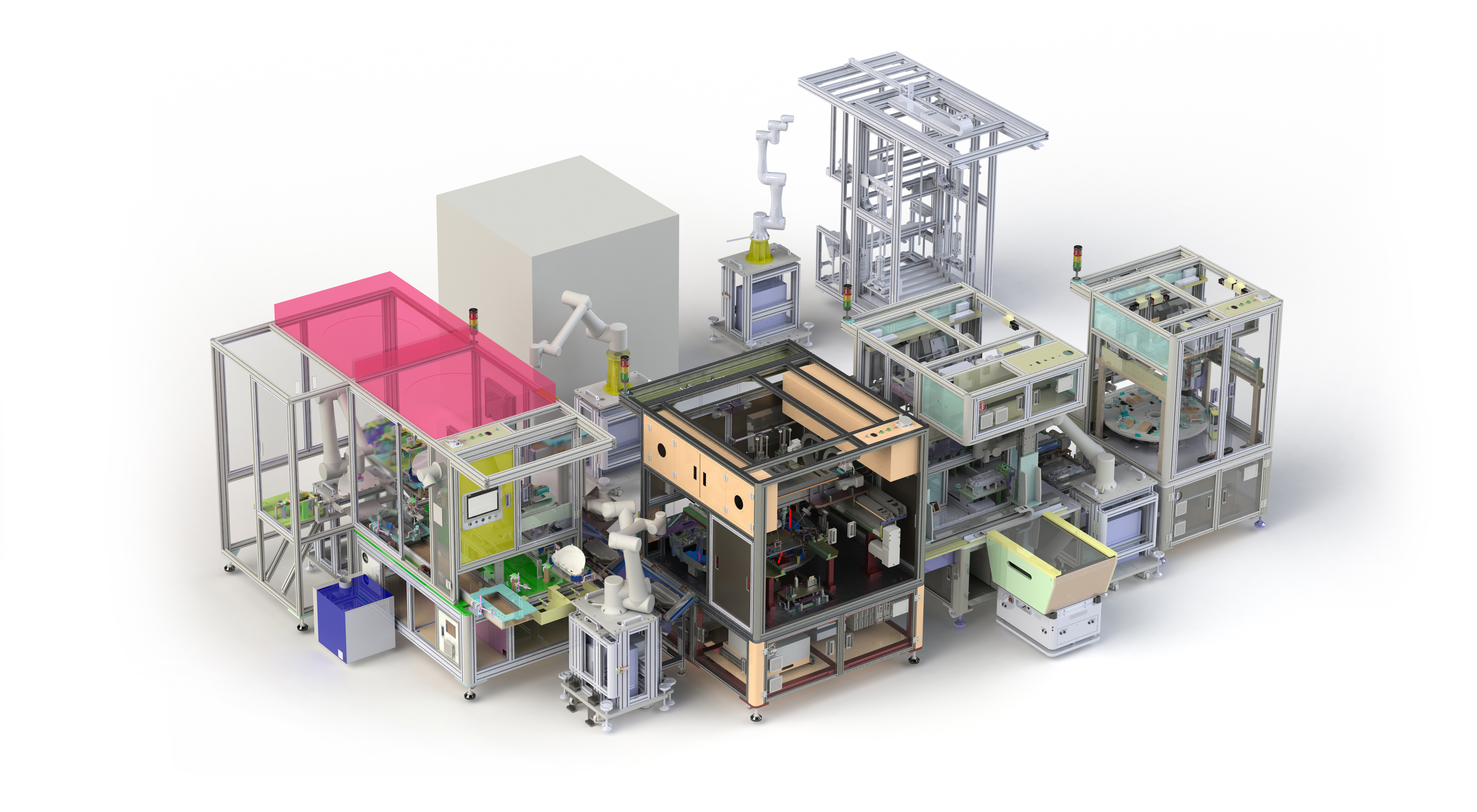

Discover the success stories of Yujin Robot Solutions in a variety of industrial sites

View solution and products case

By Solution

- Logistics Automation

- Warehouse

- Assembly Automation

- Healthcare

- Robotization

By Products

- gocart

- customamr

- assembly-automation

Blog popular Tag

It provides the location and contact information of Yujin Robot.