A 50-year-old French company that produces eyeglass lenses in over 100 countries launched a Korean division in 2003. Since then, it has built its Korean market into the most profitable sector in Asia.

In recent years, the company turned its attention to creating progressive multifocal lenses. It used a series of successful promotional campaigns to increase interest and boost the adoption rate of wearing such lenses. However, the growing demand for lenses came with increased demands on workers and production facilities. This placed workers at greater risk for fatigue, which can also lead to errors and accidents. The company was also limited by the number of hours workers could safely put in, and faced gaps between human work shifts.

To meet these increased demands, the manufacturer turned to YUJIN ROBOT.

The Problem

The eyeglass lens manufacturer had a robust production facility, but nearly all its processes were performed manually. This included picking up lenses and other items within the manufacturing facility and inserting materials in the production machine by hand. Injuries could occur either by human error or by machine malfunctions.

Because the processes were performed by humans, the company’s output was limited to how fast the workers could perform their duties. Inserting and picking up materials is a repetitive action and typically workers cannot maintain a rapid pace for the duration of an entire shift. Employees also needed to be allowed breaks throughout their shifts, which caused further production slowdowns, and a worker shortage hindered the ability to have shifts around the clock.

-2.gif?width=1200&height=390&name=2(20mb)-2.gif)

The Solution

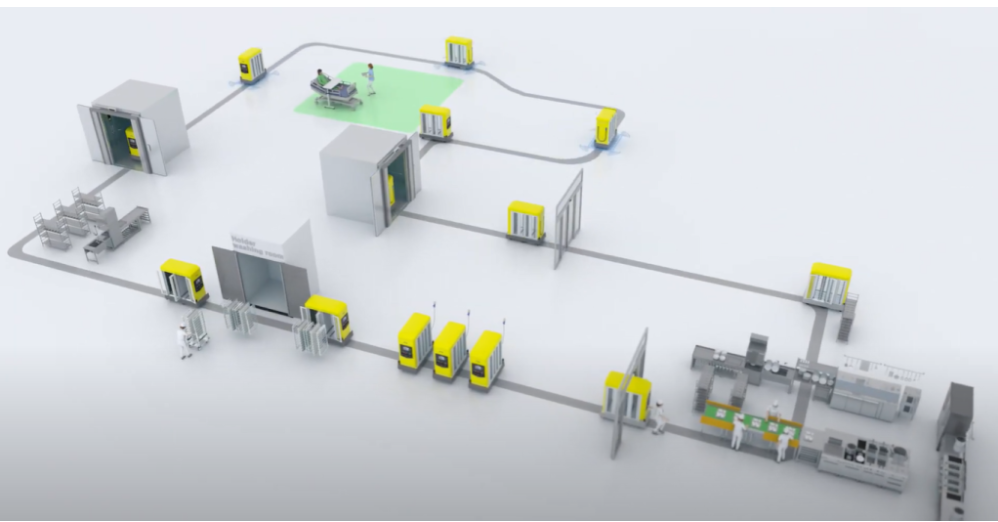

The company wanted to increase its output while also reducing worker fatigue which could lead to errors and possible injuries. It was familiar with Yujin Robot and its work and was impressed with Yujin’s experience in factory automation and autonomous mobile robots (AMRs). The eyeglass lens manufacturer consulted with Yujin to find a solution that would work within its existing environment.

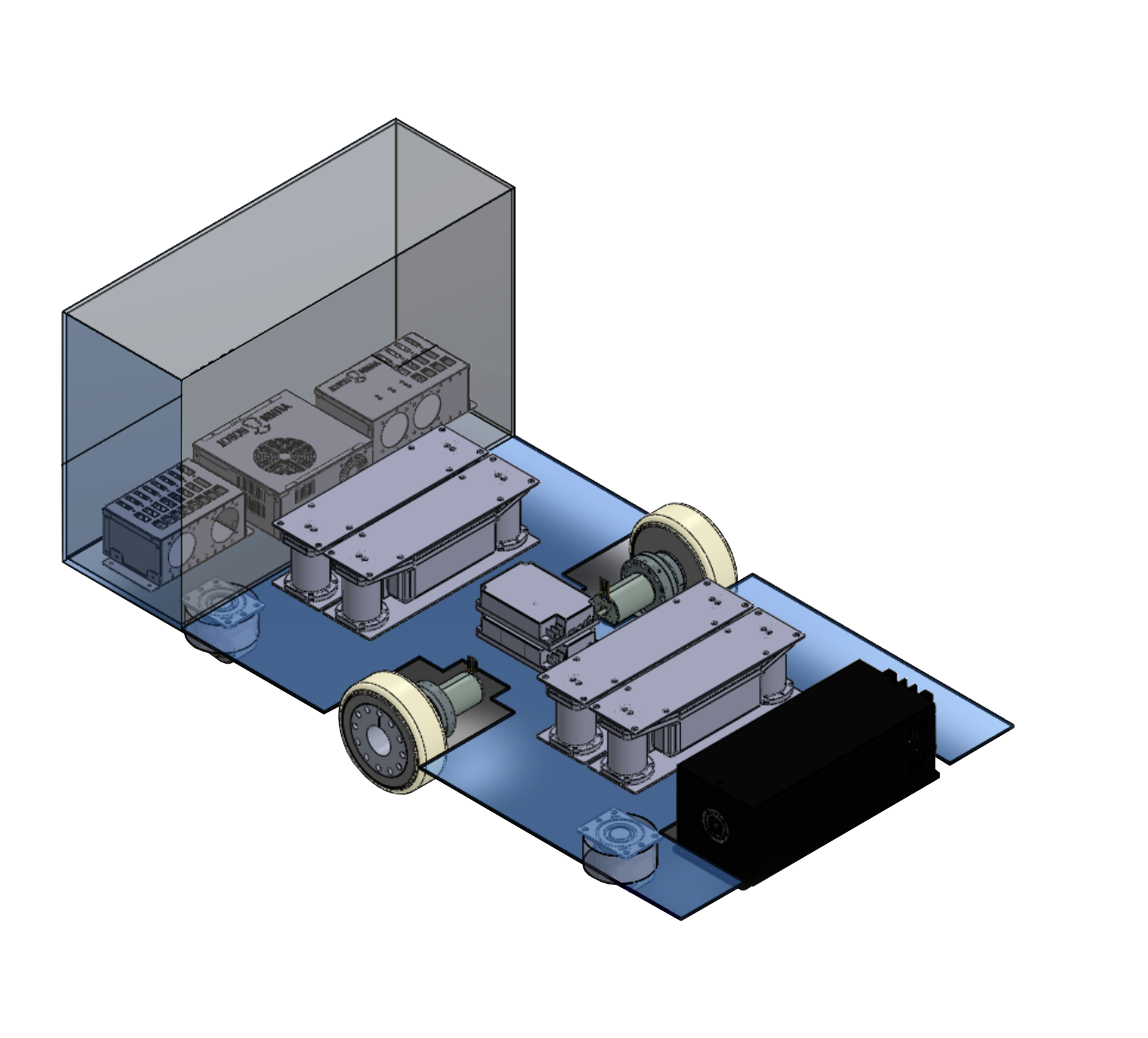

Upon reviewing the manufacturer’s needs, Yujin quickly recognized that its top module GoCart would be able to resolve many of its challenges.

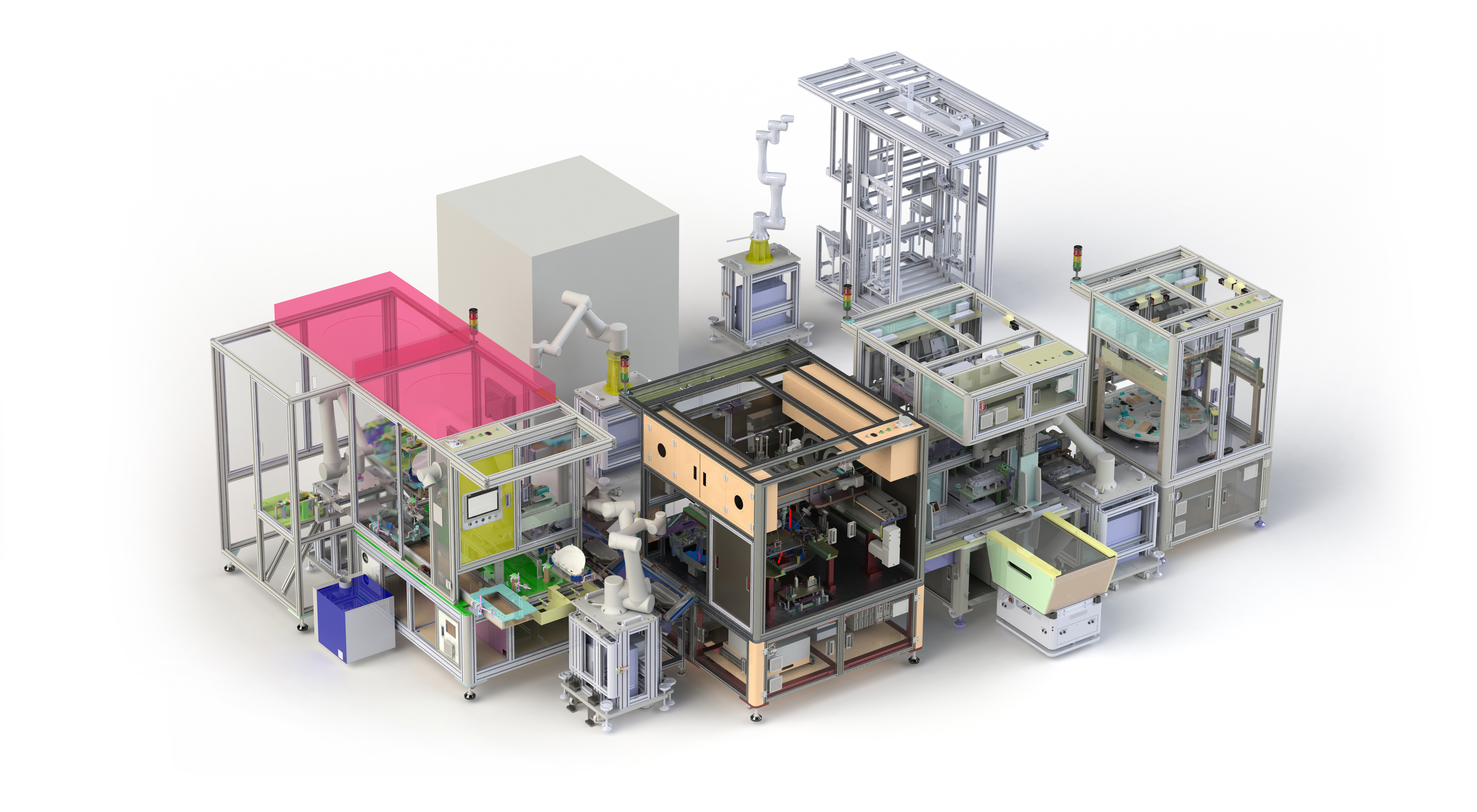

“We suggested a solution that puts two GoCarts in the manufacturing process,” said a Yujin Robot employee. One robot worked on assembling at the lens tray, while the other robot inserted lenses to receive a hard coating.

“Through this process, it could reduce the waste time and they could implement a simple, repeated action in place of a human worker.”

The manufacturer quickly discovered how well Yujin Robot’s GoCart180 integrated within its structure. The company was particularly pleased with how the fleet management system (FMS) integrated with its other equipment, namely its machines used to provide a hard coating for the lenses, to create a safer and more productive work environment, according to the head of the company’s production department. The GoCart replaced several processes, including transporting lenses, inserting them in the hard coating machines and picking them up. Using the FMS, the company is able to monitor production results and analyze productivity throughout the manufacturing facility.

After installing GoCart, the company reported it felt the robots had improved its production process and reduced worker fatigue.

The Results

Six months after implementing the Yujin GoCart, the company has been able to assign workers to higher-value tasks, providing them with greater job satisfaction while also continuing to reduce the workers’ fatigue created by performing simple tasks repeatedly. It also has been able to extend production around the clock without jeopardizing the safety of its workers.

Overall, the manufacturer has been able to create a better work environment and has seen improved morale. Instead of performing repetitive tasks, workers review the process after the AMR completes it.

Yujin’s ability to provide a customized design that ensured a smooth workflow was also important.

“We were impressed with Yujin’s experienced technological prowess and efficient management through the whole design process,” said the manufacturer’s head of production. “Yujin has a lot of experience in factory automation and AMRs, and successfully was able to consult with us on our logistics automation.”

This is the first time the lens manufacturer considered adding an AMR to its factory, the manager added. He said they were initially concerned about how the investment would pay off, both in terms of worker satisfaction and the company’s productivity and output. But the company is pleased with the results and is looking at more ways to use GoCart in its operations.

“GoCart has improved our productivity by about 20%,” he said, noting that the company is looking forward to seeing how it continues to improve its performance with help from AMRs. “Yujin Robot has been at the forefront of the robotics industry in Korea for more than 30 years and provided the total solution that we felt was better than its competitors. We are very satisfied.”