The industrial robotics sector includes technology that has been around for a few decades, like robotic arms and AGVs, as well as futuristic solutions like exoskeletons and self-healing robots. Here are nine emerging trends that can help us understand where the industry is headed.

1. Quick post-pandemic recovery of automation

When the COVID-19 pandemic hit, the outlook of industrial robotic automation was very positive, although the market reached a plateau in 2019 after years of uninterrupted growth. The prolonged emergency stopped this upward trend in its tracks, but the global Compound Annual Growth Rate (CAGR) for the period 2021-2028 is projected to be 8.9%, rising from $146.8 billion in 2020

2. Fast growth of collaborative robots

While traditional robots need to operate behind protective fences and gates, collaborative robots (cobots) work with people. Cobots are designed with built-in safety measures that make them suitable for working in close contact with humans. These measures include speed reduction and collision detection when human workers are near. Cobots typically have lightweight frames and soft, rounded edges to reduce injury in the event of an accident.

The use of cobots has been growing steadily in the past few years. Even in 2019, when the number of installations of traditional robots shrank, cobot implementation grew by 12%.

The pandemic increased the need for contactless operations, which is likely to continue pushing the demand for cobots higher in the next few years. Although their adoption rate is still low compared to traditional robots and AGVs, they are quickly catching up. The segment is expected to grow by 15% to 20% year-on-year until 2028.

3. A move beyond traditional applications

The demand for more sophisticated interactions between machines and humans is rapidly expanding the range of industrial applications of robots.

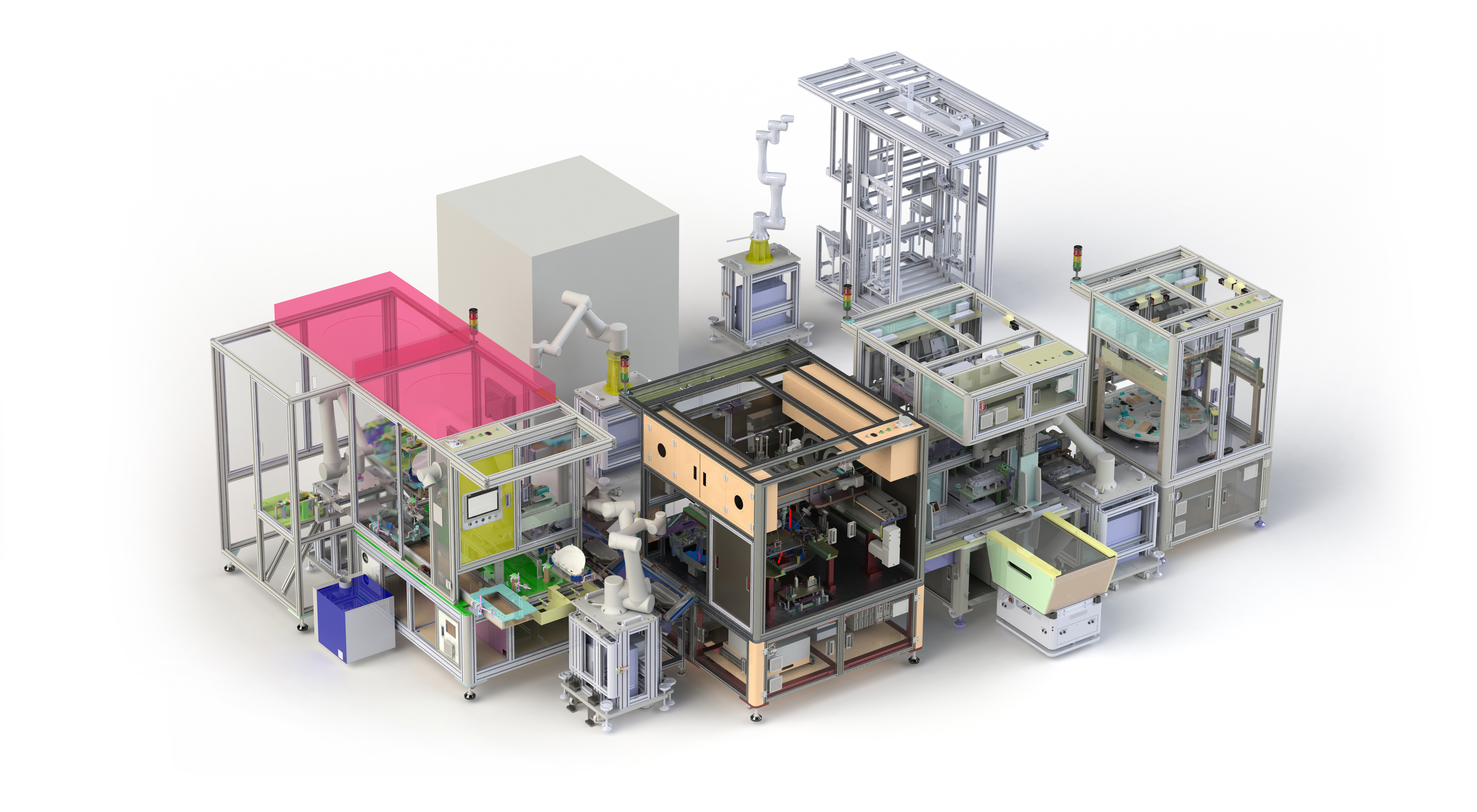

Cobots and AMRs (Autonomous Mobile Robots) are the new frontier. In addition to traditional tasks performed by traditional robotic arms, such as welding and machine tending, cobots can perform small-part assembly, and thanks to their ability to respond to human movements in real time, they can also operate alongside other workers on the assembly line.

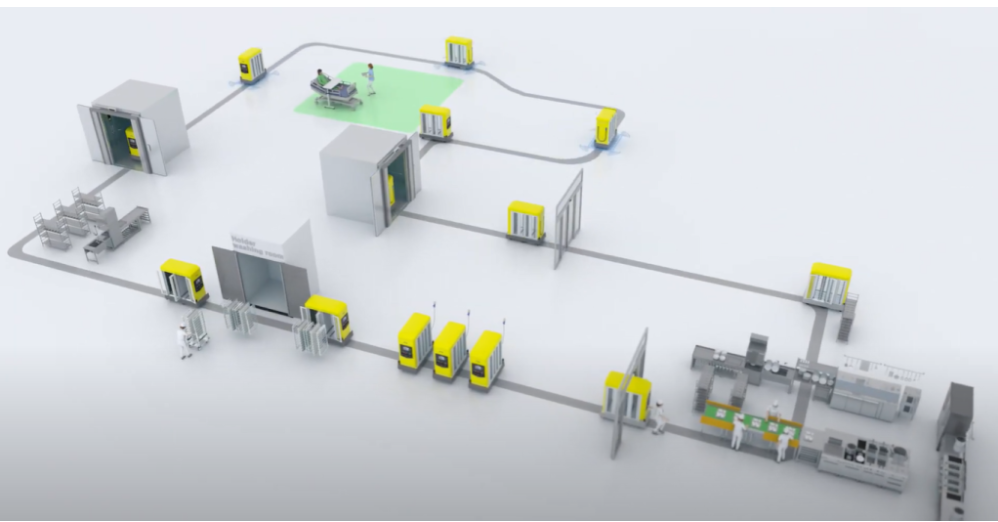

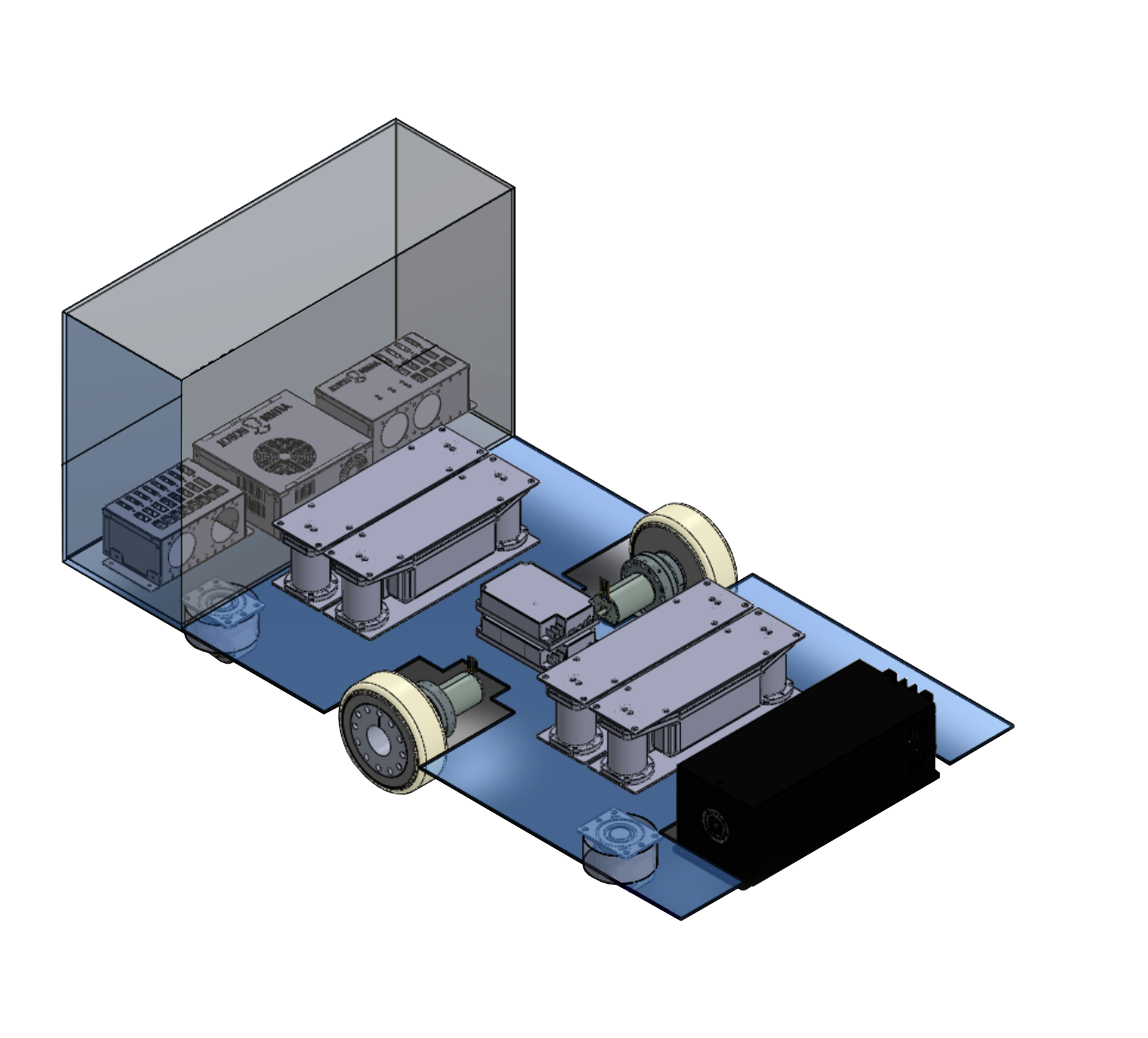

At the same time, mobile industrial robots, such as Yujin Robot’s GoCart, are finding more applications than AGVs in manufacturing plants and logistic hubs. AMRs are completely autonomous and can travel from one building to another, take elevators and go through automatic doors without guiding tracks, tapes or reflectors.

4. Lower costs

High TCO (total cost of ownership) is the biggest roadblock to a wider adoption of industrial robotic automation. The good news is that the cost has decreased by more than 50% since 1990, and the price will continue to fall by 3% to 5% per year, according to the forecast for the 2019-2024 period. The higher accessibility of industrial robotics is increasing adoption by small and medium businesses. That adoption will, in turn, lead to more production and lower costs.

5. Easier integration

The second biggest roadblock is ease of integration, which has a direct impact on the total cost of ownership. Companies want robots that integrate with their existing processes and management systems, are relatively easy and quick to implement, and don’t require hours and hours of training to operate. The market is responding to this demand with more computing power and more powerful networking technologies that are making integration easier. In the longer term, industrial robotics buyers hope to establish a common programming platform for faster customization.

6. Electronics as the leading segment

Automotive has traditionally been the industrial sector with the highest number of installations of robot installations. The trend has now shifted, with electronics now leading the market. According to a forecast by Interact Analysis, the segment will experience the fastest adoption of robots in the post-COVID-19 period, with 123% growth by 2023 compared to 2019.

7. Remote monitoring

Centralized monitoring is becoming an integral part of automation solutions. Again, the need for integration is the drive behind this trend. Robots are expected to interact safely with humans while also working with one another and with existing automation systems. An example of such a system is Yujin’s Mobile Platform for autonomous mobile robots, a fleet-management system that controls the industrial robots and monitors their status.

8. Use of big data

While remote monitoring is becoming an established trend, the next phase in its evolution is already taking shape: the use of big data to improve processes and prevent faults. Although the cost of industrial robots is constantly decreasing, they still represent a considerable investment, especially for larger manufacturers. In order to speed up ROI, it is important to maximize efficiency and uptime. This is made possible by leveraging the large amount of data generated by robots and autonomous vehicles to improve predictive analysis and preventative maintenance.

9. More up-skilling opportunities

A worrying emerging trend in industrial robotics is the lack of skilled technicians to install and operate these machines. According to a report by McKinsey, the fast adoption rate of industrial robotics will make the dearth of talent even worse in the short term. This issue is making many businesses aware of the importance of providing specialized training to part of their workforce. For industrial workers, this represents an important opportunity for up-skilling and increasing the value of their role within their company.

Overall, these nine trends draw a very positive picture for the immediate future of industrial robotics. The key words are “more” and “better” — more growth, more applications, better accessible technology and more opportunities for the workforce.