GoCart provides an autonomous mobile transport solution for pharmaceutical delivery and hospital intralogistics

Autonomous mobile robot (AMR) systems like the GoCart fleet are revolutionizing the ways in which hospitals and healthcare facilities handle pharmaceutical delivery and intralogistics processes, improving quality of life for both the workers and the patients. Here we will investigate the current challenges that AMR solution both addresses and faces in being implemented into the existing hospital and healthcare systems.

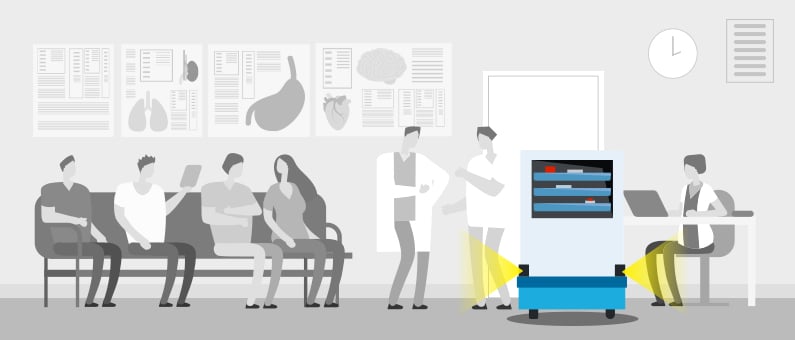

Many hospitals currently use pneumatic tube and rail systems for small batch (under 5 kg) material transport, such as documents, drugs, and blood samples. AMRs, albeit a slower alternative, can transport heavier loads, with carts atop AMRs carrying meals, linens, IV-pumps, and other medical equipment across hallways, rooms, floors, and even buildings, while autonomously navigating and avoiding collision through the crowd. The annual maintenance cost for the pneumatic tube systems can be a significant financial burden. Furthermore, pneumatic tube and rail systems are not flexible to route changes, whereas AMRs are highly versatile and seamlessly adaptive to structural alterations.

Despite these relative advantages that AMRs have over the current transport infrastructure, introducing AMRs are not without challenges, the first of which is the cost. Each AMR is priced at thousands of dollars, with peripherals, management software, and commissioning costs racking up the price. The initial investment may thus seem burdensome and the ROI questionable from the hospital’s standpoint. Moreover, publicly funded hospitals are often working with tight operational budgets and the ROI for longer-term investments into technology is not of the highest priority compared to those in the private sector, who are usually driven by competition and the need to maximize productivity.

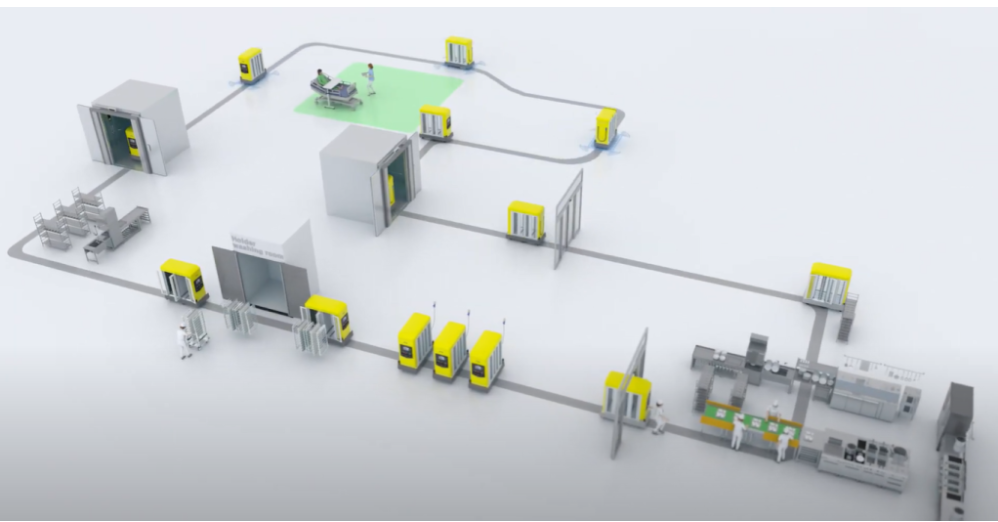

At the same time, the subject of cost is a double-edged sword. Hospital intralogistics management budget is a huge portion—40%—of the total hospital budget and is one of the major factors determining the hospital’s nonetheless competitive positioning, according to the 2018 research conducted by Korea Institute for Robot Industry Advancement. Therefore, any improvement in expediting the intralogistics process, such as through AMR implementation in material transport, would benefit the hospital tremendously. A multi-robot system would further achieve this as the fleet management system (FMS) optimizes the workflow of the AMRs by coordinating their jobs along the most efficient transport routes. The International Federation of Robotics reports that the use of AMRs is estimated to reduce the cost per delivery by 50~80% and the average distance that a nurse walks each day by 3~4 miles in a typical 200-bed hospital.

At the same time, the subject of cost is a double-edged sword. Hospital intralogistics management budget is a huge portion—40%—of the total hospital budget and is one of the major factors determining the hospital’s nonetheless competitive positioning, according to the 2018 research conducted by Korea Institute for Robot Industry Advancement. Therefore, any improvement in expediting the intralogistics process, such as through AMR implementation in material transport, would benefit the hospital tremendously. A multi-robot system would further achieve this as the fleet management system (FMS) optimizes the workflow of the AMRs by coordinating their jobs along the most efficient transport routes. The International Federation of Robotics reports that the use of AMRs is estimated to reduce the cost per delivery by 50~80% and the average distance that a nurse walks each day by 3~4 miles in a typical 200-bed hospital.

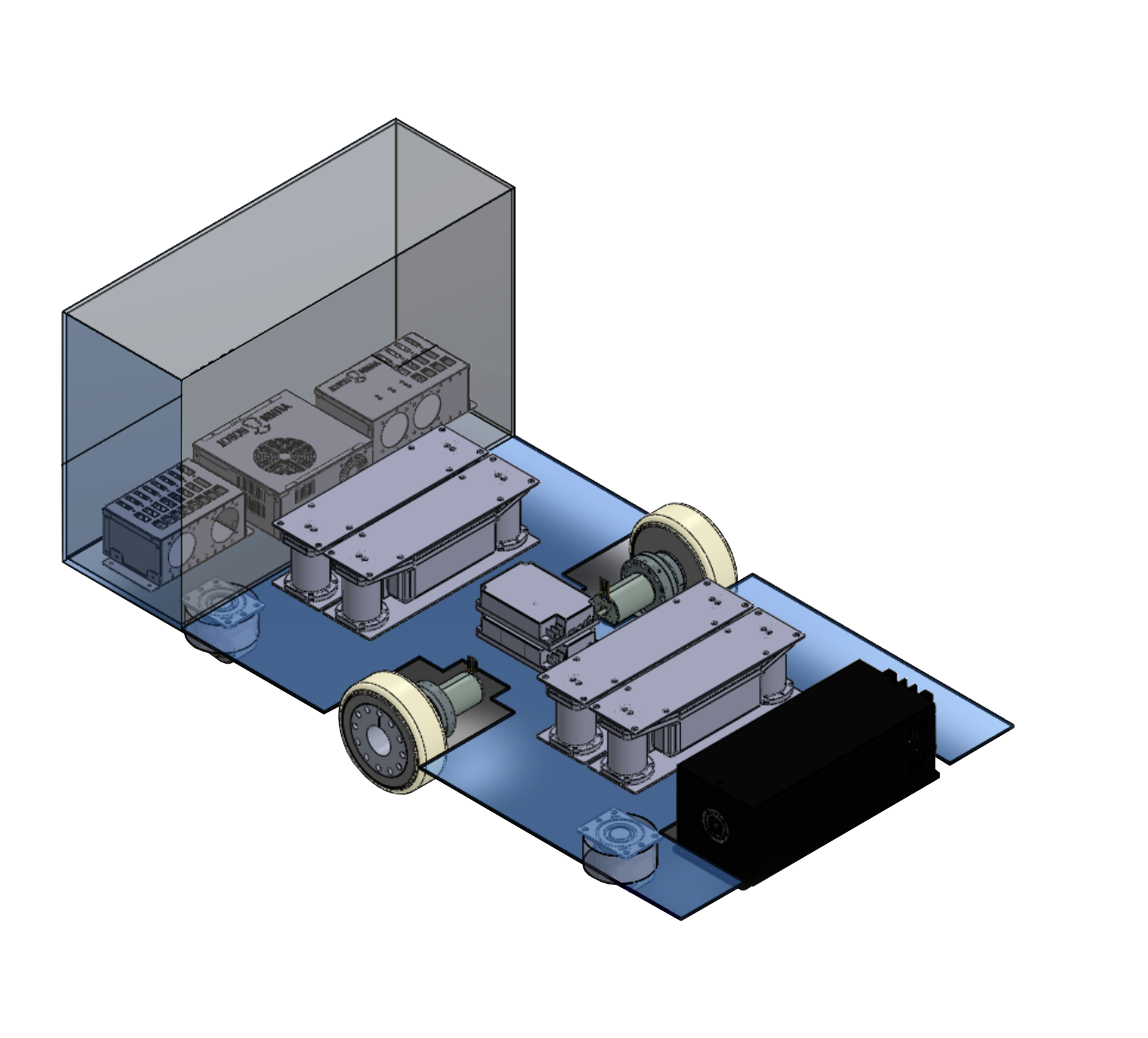

For ideal AMR performance, the AMR must be able to traverse across the different floors and buildings as aforementioned, which requires interfacing with elevators and automatic doos. Yujin’s Fleet Management System (FMS) enables elevator and automatic door integration that allows each GoCart to travel and deliver boundlessly throughout the facility. For elevators that do not have the appropriate system requirements for the AMR server control, Yujin collaborates with elevator manufacturers to upgrade the server accordingly. Going forward, Yujin is looking to cooperate with various global elevator and automatic door manufacturers for a wider set of integrated and connected devices as communication protocols and standards for interfacing with elevators and doors continue to develop to facilitate a broader AMR implementation.

All in all, AMR integration in hospitals and healthcare facilities opens doors to loads of benefits not always directly captured by ROI. In addition to the increased efficiency and performance from the robot’s tireless 24/7 availability, robotic implementatioin general minimizes injuries, errors, training, and turnover associated with human workers. Delegating menial tasks such as delivery to robots is shown to result in not only improved service and patient satisfaction, but also improved psychological state and motivation level for the workers. By reducing walking time for personnel, human locomotion is restricted overall, minimizing risk to contamination via human contact. AMRs hence offer a sanitary transport solution necessary for sterile pharmaceutical goods and medical equipment and for patients who are prone to complications from the transmission of infections, especially in COVID-19 times.

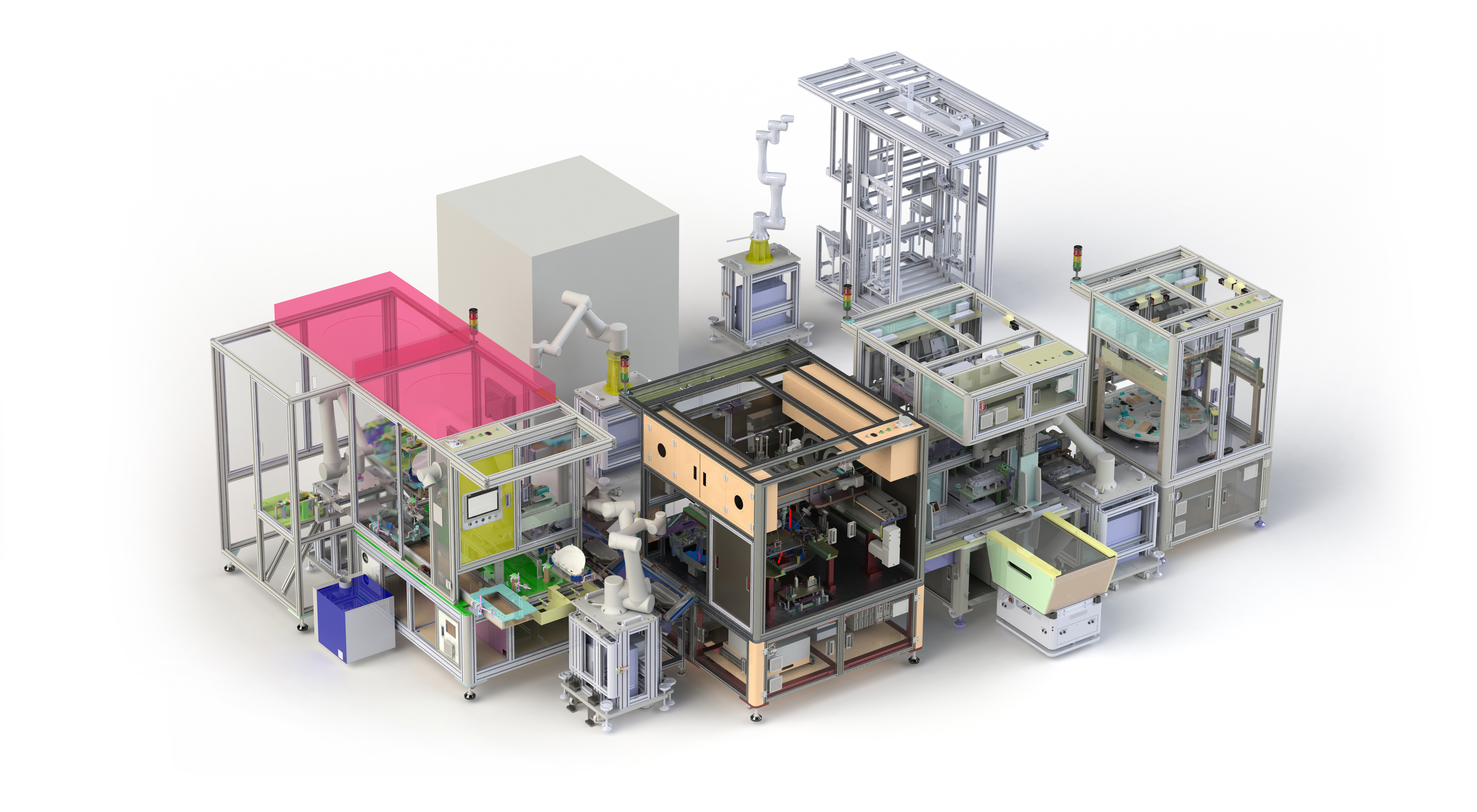

Despite these benefits, hospitals and healthcare facilities may still be resistant to implementing robotic solutions due to tight budget constraints, rendering automating the intralogistics and delivery processes using AMRs a relatively immature market. However, the dwindling number of healthcare workers and the resulting labor shortage will surely spur the adoption of AMRs at an increasing rate. And as the new technologies for the AMR components and the assistive tools for its production and installation continue to develop, the uptake of these technologies in the medical fields will be more cost-effective and further accelerated in the days to come. Yujin Robot with its GoCart series stands at the forefront of this quickly expanding market in partnership with Sumetzberger, Aircom Group, Kukje E&T, and TAG Industrial and is dedicated to transforming the life of hospital and healthcare workers and patients alike.