DPS Cart AMR Solution applied

Minimize movement and work time in conjunction with AMR and maximize order picking work efficiency

Discover the success stories of Yujin Robot Solutions in a variety of industrial sites

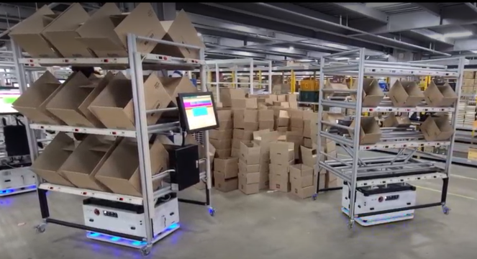

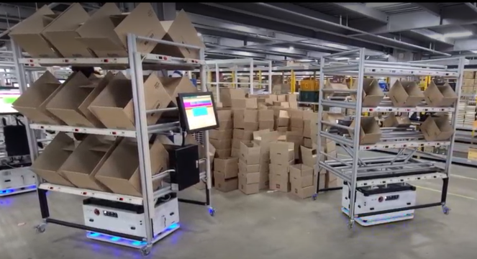

DPS Order Picking Solution through GoCart

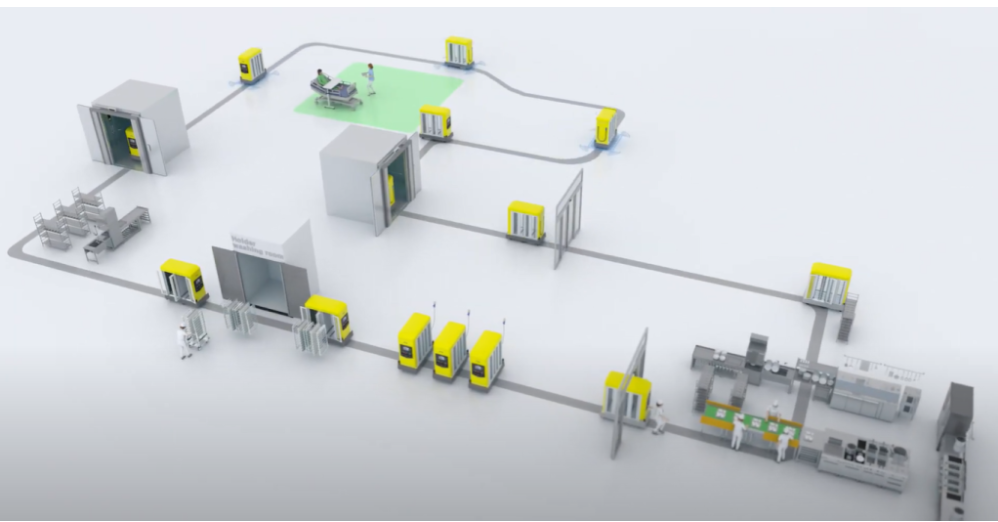

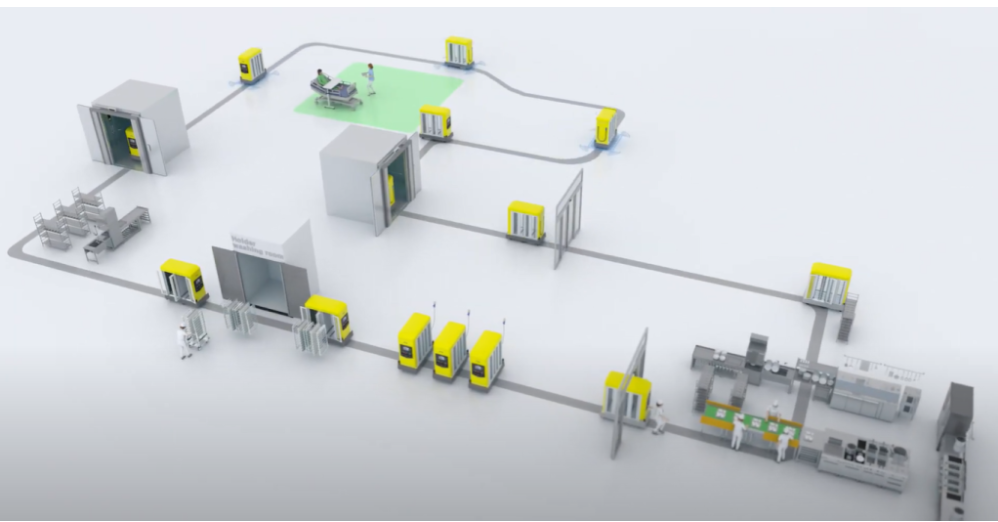

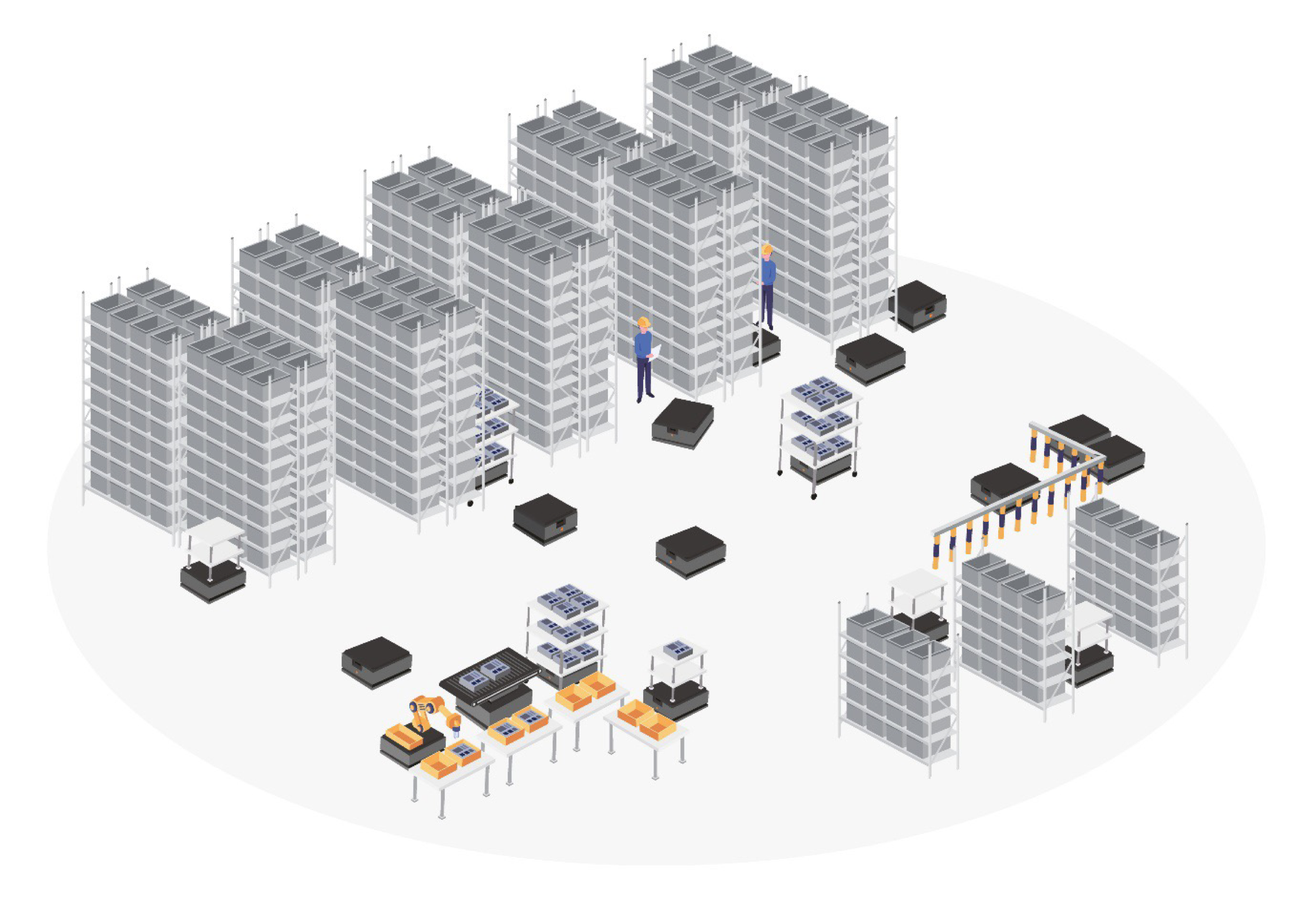

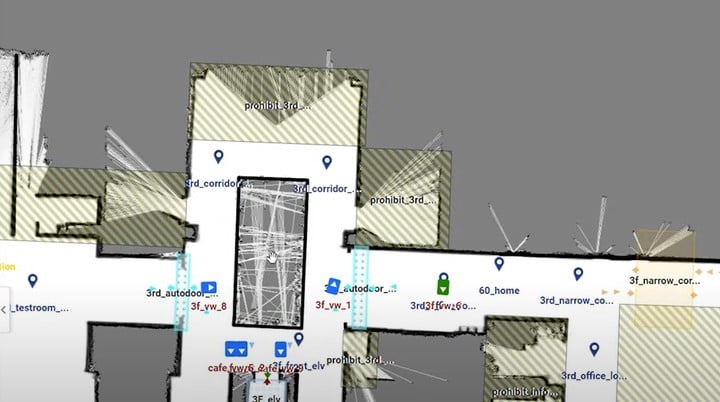

YUJIN ROBOT applies logistics automation based on autonomous driving mobility technology to various areas ranging from industrial sites to daily life. Based on the technology of Korea's first-generation robot company, we have independently developed robot component units such as SLAM, Navigation, and 3D LiDAR, and provide end-to-end robotics solutions in factories, warehouses, and hospitals through GoCart, an autonomous mobile platform. Through our solutions, we complete a logistics automation system that increases production efficiency and provides customer satisfaction and value.

YUJIN ROBOT's warehouse automation solution is based on DPS (Digital Picking System), which digitally displays the picking quantity on a digital indicator frequently used in logistics sites, allowing anyone to quickly and accurately perform order picking without a separate slip to help you complete your work. In addition, by combining with GoCart, an autonomous AMR, DPS Cart accurately transports products to a designated location without separate operator intervention.

The DPS AMR solution is a solution that allows a cart combined with the DPS system to move to a designated location with an autonomous robot without additional operator intervention. Carts equipped with DPS digitally mark the boxes to be placed in each product location by matching them with the products to be picked, and help transport products without a separate slip.

Optimization for small quantity batch production, multi-frequency type of logistics environment

Sorting by cart unit and product order possible

Improved picking efficiency by minimizing movement lines

Picking and inspection can be performed simultaneously and support productivity and index management functions.

Electronic indicators provide location guidance for each category and eliminate erroneous work.

Reduce errors in work, fast and safe productivity through DPS Cart System

Preventing worker injuries and creating a pleasant working environment

Eliminates unnecessary costs and enables efficient manpower composition

Minimize movement and work time in conjunction with AMR and maximize order picking work efficiency

Supports various upper devices tailored to customer environment and work process

더 많은 사례보기

Check out more information about our AMR products for healthcare, factory and warehouse applications

Max. Payload: 180 kg (396.83 lbs)

Operating Speed: Max 1.0 m/s

Max. Payload: 250 kg (551.15 lbs)

Operating Speed: Max 1.0 m/s

Max. Payload: 500 kg (1,102.31 lbs)

Operating Speed: Max 1.0 m/s

Max. Payload: 1000 kg (2,204.62 lbs)

Max. Payload: 1500 kg (3306.93 Ibs)

Operating Speed: Max 1.0 m/s

Max. Payload: 200 kg (440.92 lbs)

Operating Speed: Max 1.0 m/s

Check out the videos of our application in our YouTube channel

Product brochure is available for download.

Standard AMR

Max. Payload: 180 kg

Operating Speed: 1.0 m/s

Loading Surface Dimension (L x W): Max. 646 x 441 mm (25.43" x 17.36")

Driving Method: Differential

Max. Payload: 250 kg

Operating Speed: 1.0 m/s

Loading Surface Dimension (L x W): Max. 840 x 640 mm (33.07" X 25.19")

Driving Method: Differential

Max. Payload: 500 kg

Operating Speed: 1.0 m/s

Loading Surface Dimension (L x W): Max. 1222 x 822 mm (43.30" x 30.31")

Driving Method: Differential

Max. Payload: 1000 / 1500 kg

Operating Speed: 1.0 m/s

Loading Surface Dimension (L x W): Max. 1222 x 822 mm (48.11" X 32.36")

Driving Method: Differential

-2.png)

Max. Payload: 200 kg

Operating Speed: 1.0 m/s

Loading Surface Dimension (L x W): Max. 897 x 697 mm (35.31" x 26.73")

Driving Method: Omni Directional