The Great Resignation that began during the pandemic has continued into 2022, leaving many industries scrambling to find workers while simultaneously trying to keep up with the demand for more services and products. According to the

Bureau of Labor Statistics 4.5 million people quit their jobs in March 2022, which was 152,000 more quits than the previous month — and left a record 11.5 million jobs unfilled.

These resignations have affected virtually all industries and shaken global supply chains and fulfillment operations. Resignation rates in warehouse and transportation environments continue to hover just below the 3% mark, and manufacturing has been among the hardest hit industries, with a nearly 60% jump in resignations since the pandemic began.

With no signs of resignations slowing down, the materials handling industry faces ongoing challenges. Not only do warehouses need to retain their existing workforce, but they are also trying to hire and train new workers. A March 2022 reader survey from Modern Materials Handling found that 52% of warehouses faced a shortage of forklift technicians, and 51% said it was “somewhat of an issue” to find capable technicians for forklifts and other material handling systems.

And, as the workforce gets older, and more younger people choose not to go into industries that they perceive as being “dirty” or dangerous, warehouses can expect their challenges to continue.

There’s also a third area of concern beyond resignations and dwindling eligible hires: workplace injuries. Strained and sprained muscles, cuts and fractures all contribute to warehouse workers needing time off. Back injuries are the most common type of sprain or strain, with the National Safety Council noting these injuries require an average of 57 days off. But forklifts overturning are responsible for about 24% of all material handlers’ injuries and require as much as three months of recovery.

All of these add up to more headaches (and costs) for the materials handling industry. As most hiring managers know, the high price of turnover goes far beyond the cost associated with finding a new worker, such as advertising, screening costs, drug testing, training, uniforms, etc. There are also soft costs that include things like lowered productivity as a new employee gets up to speed, damage to a company’s reputation due to delays or errors created by a worker shortage and unhappy customers resulting from mistakes made while unloading, picking and packing.

With the Bureau of Labor Statistics putting the annual warehouse turnover rate at 43%, and no end to the labor crunch in sight, it’s time for companies to begin looking at other options to keep operations running efficiently and on time.

Working Around Worker Shortages

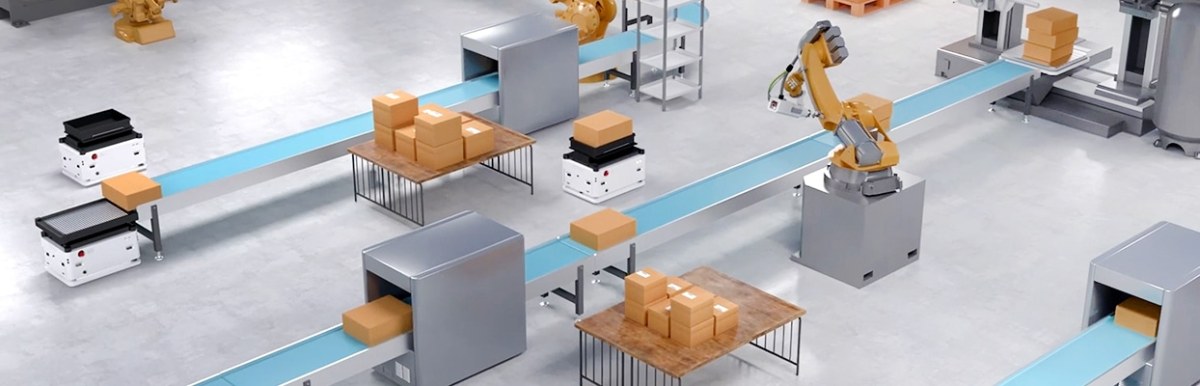

In the absence of qualified, available workers, the materials handling industry is among those looking to the

benefits of using robots. While employees once feared that robots would take their jobs, instead the robots are taking the jobs that are being abandoned and have trouble being filled. There are some jobs that humans can do better than robots, but certain tasks are better suited to robots.

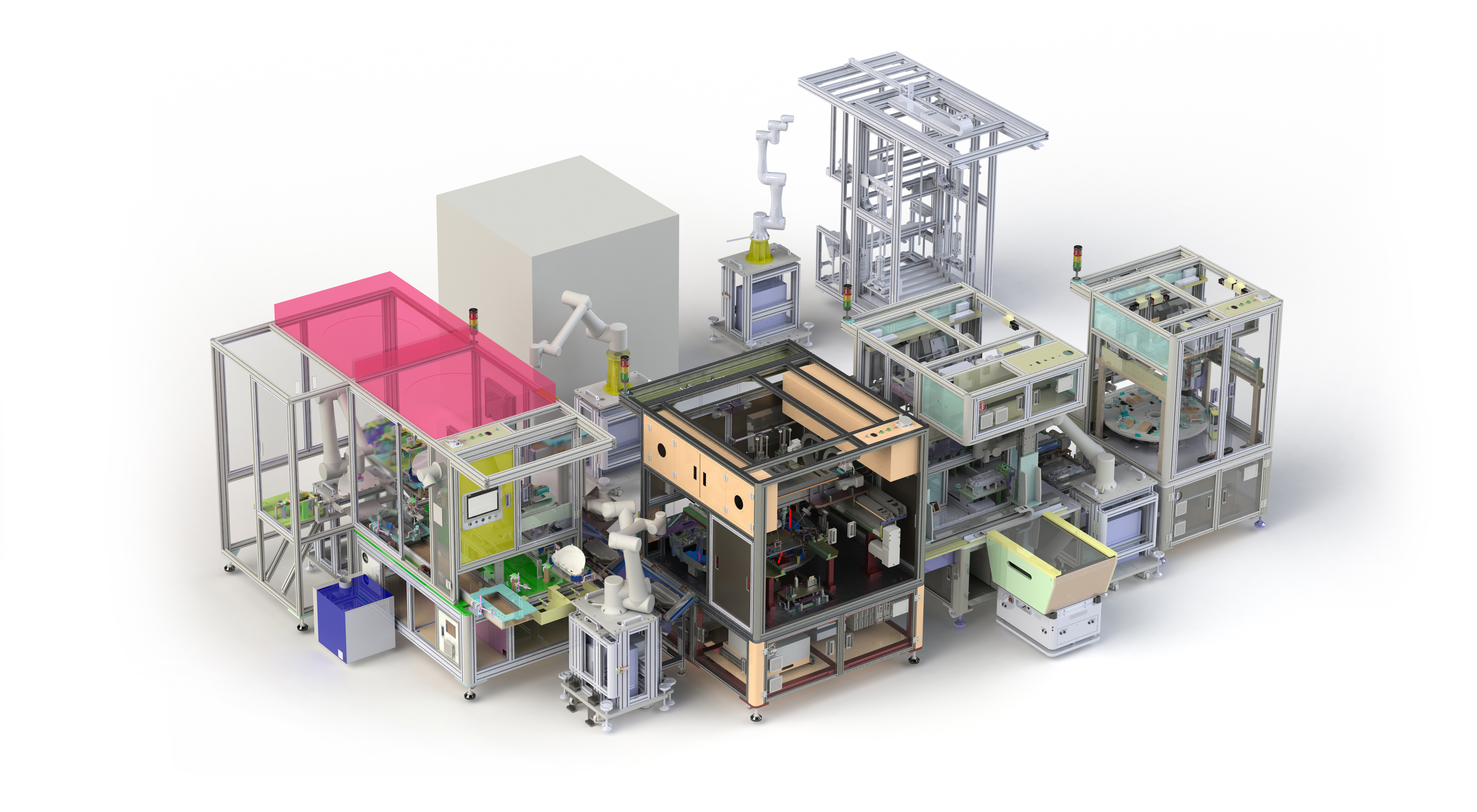

And, when working alongside human employees, robots and automation can improve both productivity and the overall work environment. Moving to an automated warehouse system can not only help cover the gaps left by worker shortages but can also help reduce the number and severity of on-the-job injuries.

Some of the main drivers of warehouse workers leaving their jobs include wanting less physical and mental stress, wanting more professional opportunities and boredom with their current position. The advantage of automation is that it can fill the jobs that don’t feel rewarding to human workers, creating opportunities for them to take on other roles they might find more rewarding and less physically demanding.

Warehouse automation also increases efficiency for human material handlers, who don’t have to walk to different picking points, pushcarts or pick up heavy items, and that improved efficiency directly affects a company’s profitability.

Built for the Warehouse Environment

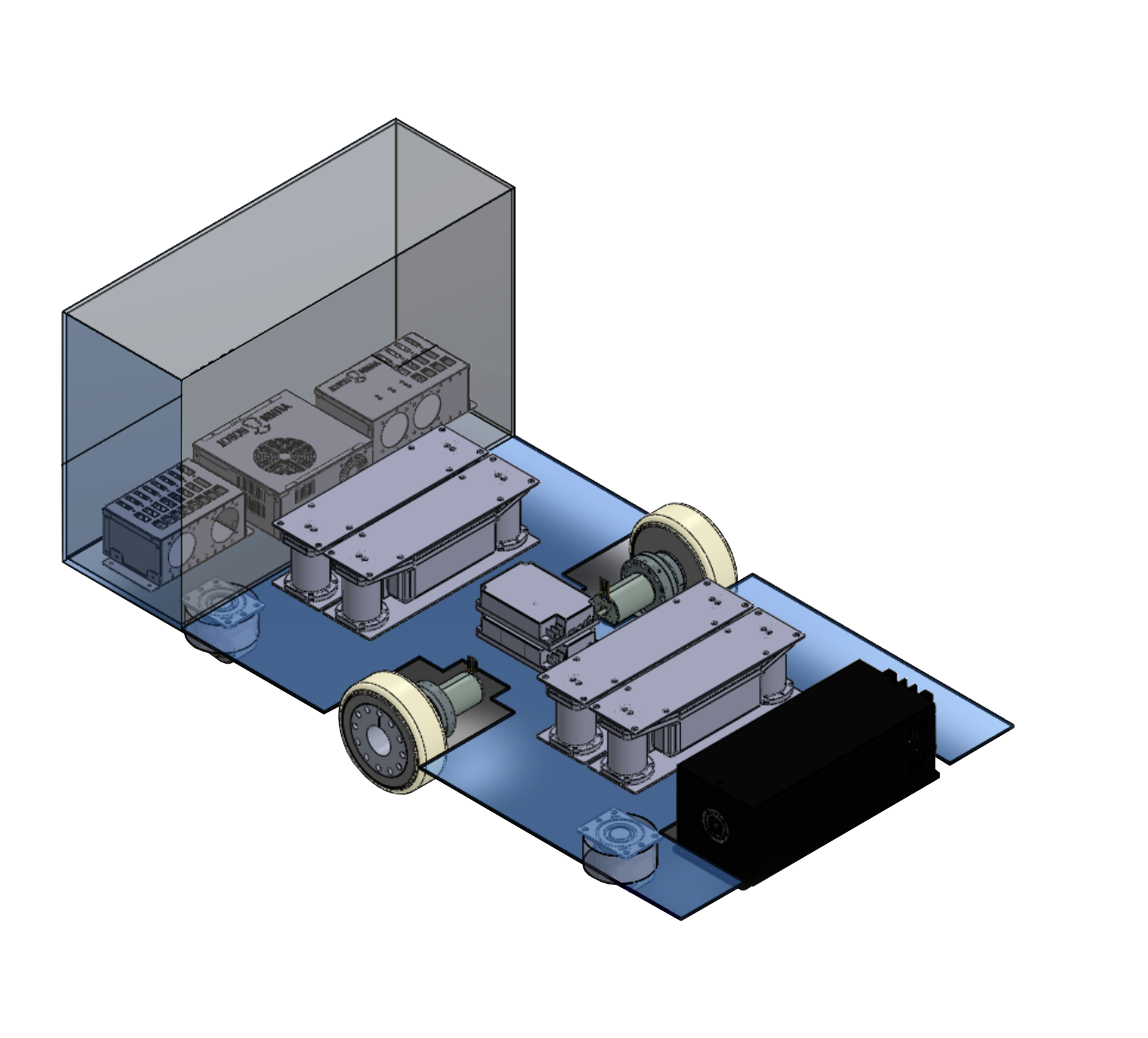

There are two types of robots that are well-sited for the warehouse environment: autonomous mobile robots, or AMRs, and automated guided vehicles, or AGVs. They both have the advantage of being able to work around the clock and don’t require sick days or lose productivity because of fatigue. Basically, a robot is as energized and productive at 8 p.m. as it was at 8 a.m.

AMRs are the perfect complement to a human workforce. If they are needed to perform a different task, downtime for training isn’t required; they simply need to be retasked. Because they have an intelligent navigation system, they can travel throughout the environment using sensors and cameras that allow them to avoid collisions, improving efficiency along with workplace safety.

They are particularly beneficial in materials handling facilities when it comes to replacing equipment like carts and tuggers. While such equipment has been a mainstay of warehouses and helps move large loads around a warehouse, they also have issues with maneuverability, as they can’t manage sharp turns or fast stops — and are a notorious source of accidents.

\With a materials handling robot, large loads can be moved safely and efficiently through a crowded warehouse, and they don’t need a human driver to do it. Robotic AMRs, such as the GoCart series from Yujin Robot, provide a safe alternative to casters that must move heavy loads. Under human supervision, these loads can quickly become dangerous when they shift or make a sudden movement; an AMR can stop quickly if it encounters an obstacle or if a worker steps in its path — meaning that it’s a safer environment for everyone.

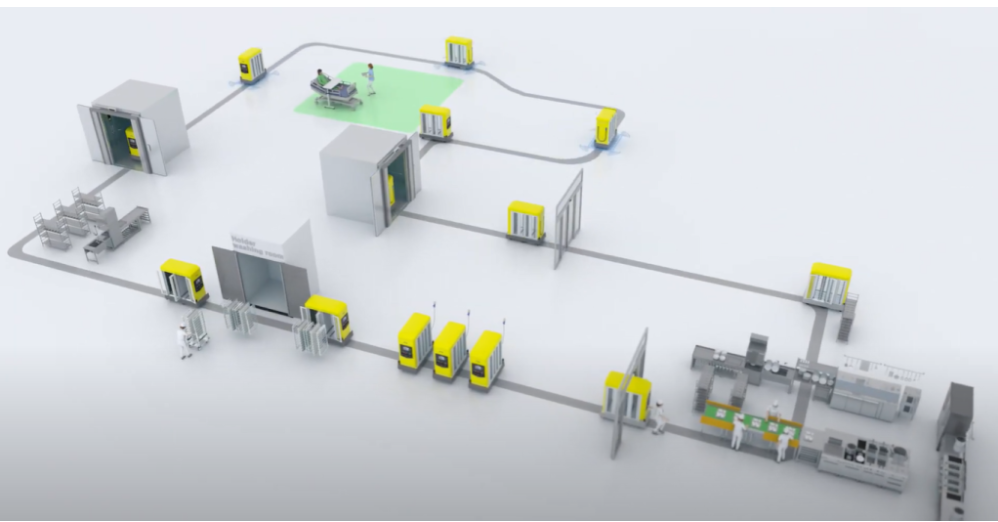

AGVs are also used in warehouses, distribution centers or manufacturing facilities to do jobs that are typically handled by equipment including carts and conveyor systems. These vehicles can travel throughout their environment following a set, defined pathway and can streamline operations while improving safety.

A fully autonomous forklift, for example, is usually smaller than manual forklifts, which means it can be used in tighter spaces and reduce the amount of human lifting or exertion that is required. Like AMRs, they reduce the number of steps workers need to take in large warehouses, manufacturing or distribution centers, which eases worker fatigue while also speeding up operations.

One of the notable differences between AMRs and AGVs is that AGVs require a predetermined route, which can include magnetic guide tape, wired navigation, laser target navigation and geoguidance. One of the most commonly used navigation technologies is based on LiDAR, which gather data about an object’s surroundings and uses high-frequency light pulses to help autonomous equipment navigate its course — even in close quarters.

Improving Operations Through Automation

Companies looking to offset the ongoing worker shortage can benefit from automation in many ways. In addition to improving conditions inside the warehouse, automation also improves customer loyalty and can increase profitability due to better operational efficiency and productivity.

Technology allows multiple options for creating an autonomous warehouse environment; it’s simply a matter of finding the solution that works best for each individual setting. To learn more about how automation can meet your individual needs, download our materials handling white paper,