Autonomous mobile robots (AMRs) are working their way into multiple industry sectors, making processes more efficient, boosting employee productivity and even improving patient safety in healthcare. From retail to distribution environments to healthcare settings, AMRs are providing significant advantages at a time when all sectors face worker shortages and health/safety concerns.

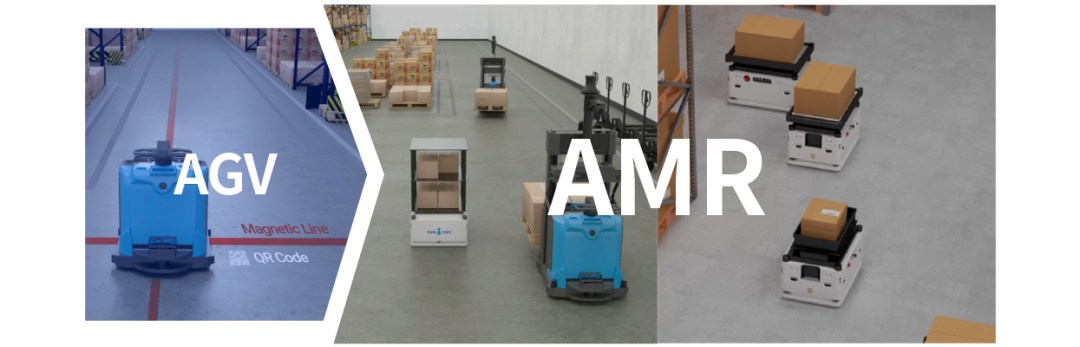

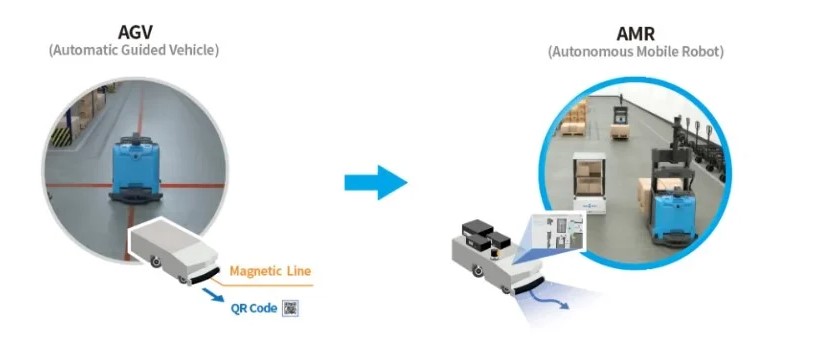

Warehouse automation has become one of the primary solutions to help companies meet demand at a time when finding workers has been challenging. In the first quarter of 2022, robot sales increased by 40% — and that follows a 21% overall increase in autonomous technology purchases. Companies that are looking to convert manual operations to an automated environment, or to turn automated guided vehicles (AGVs) into AMRs, can enjoy significant benefits. Here’s a look at what robotization packages are, how they work and what benefits they provide for warehouse environments.

What is a robotization package?

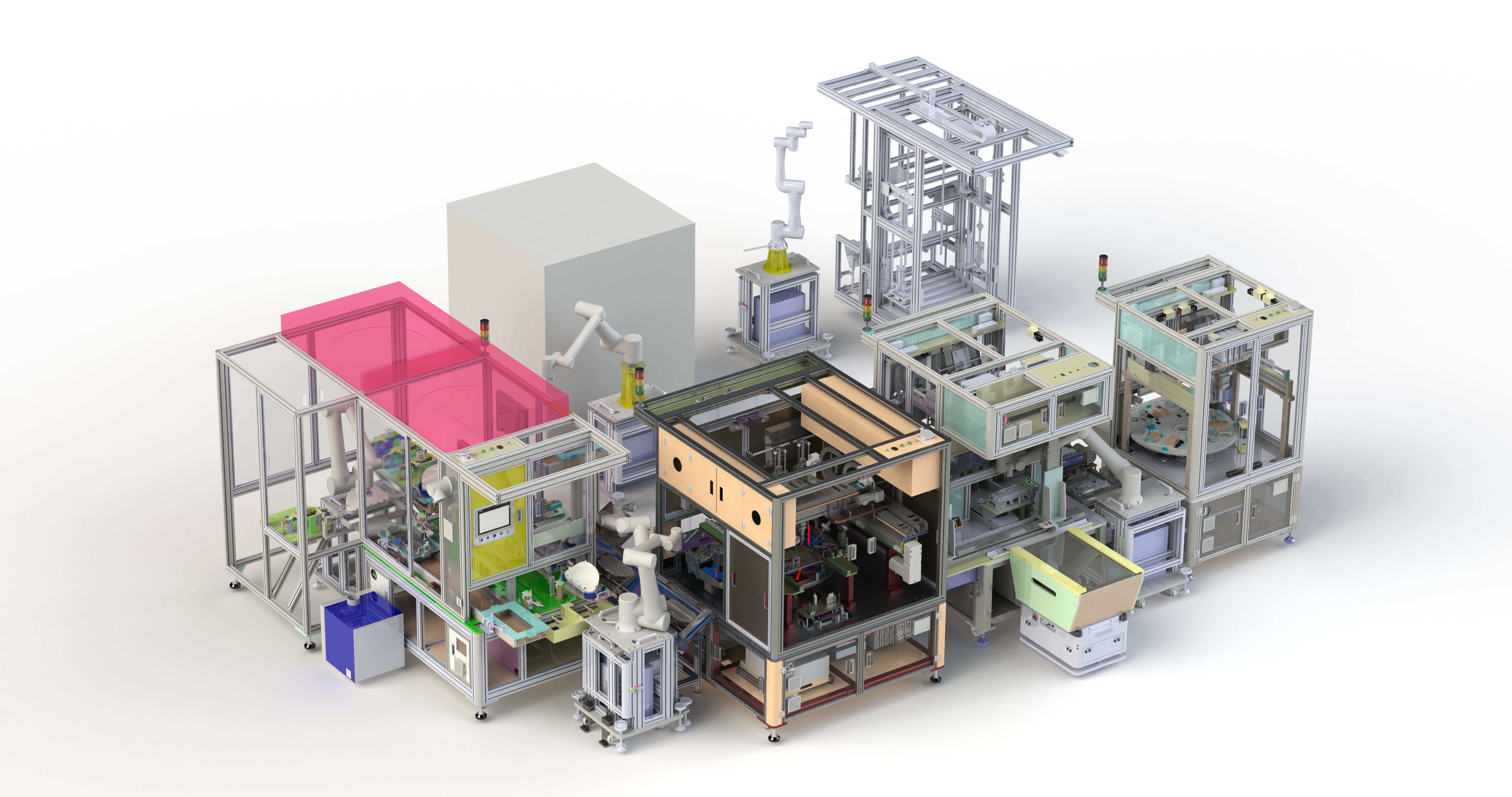

By now, the idea that robots are helping humans perform their jobs better is becoming widely accepted. Robotization is the process used to turn existing machines into AMRs and is a solution that’s available for many types of devices.

Manual devices such as hospital delivery carts, retail shopping carts and forklifts, and other warehouse equipment requiring a driver can all be transformed into AMRs. To do this, the manual equipment is retrofitted with three important components to create an autonomous mobility solution (AMS).

SLAM and Navigation Software. This is required to help the AMR follow its course. It includes localization and mapping features, as well as path planning, tracking, obstacle detection and avoidance. In other words, it lets the AMR determine where it needs to go, create a plan to get there and avoid hitting any obstacles along the way.

Driving technology. AMRs use two types of driving technology: differential drive and mecanum drive. The differential drive has two independent wheels mounted on either side of the robot, which enhances its ability to change direction. The mecanum drive allows the robot to move in any direction without changing how the robot is oriented.

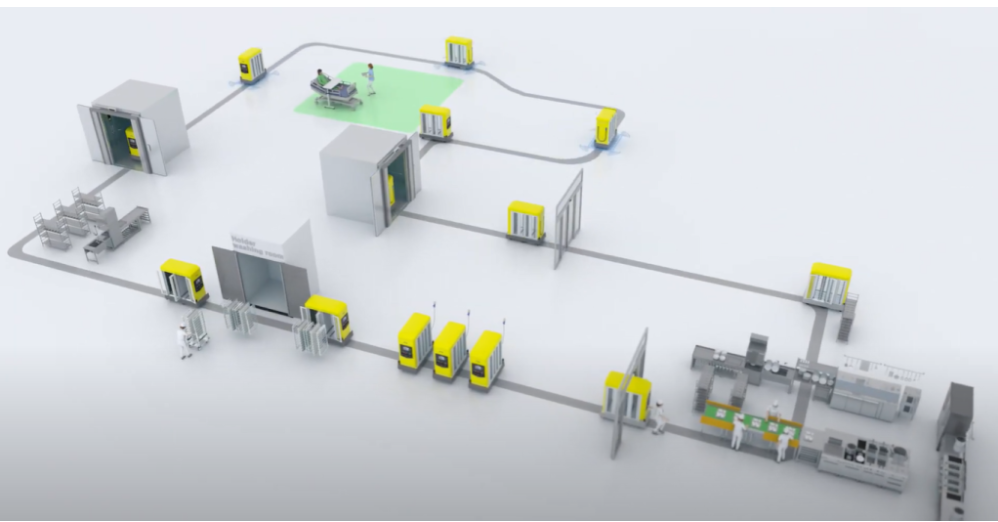

Sensors. In our robotization packages, we use YUJIN sensors with 3D LiDAR, as well as a depth camera and an inertial measurement unit (IMU) sensor that allows it to measure such things as orientation, velocity and gravitational force. When these three components are integrated into an existing device, it can become an AMR. As part of that robotization, they can now be managed autonomously through a fleet management system that allows a human operator to manage 2D maps of the work environment, monitor multiple devices and control traffic patterns, manage resources such as elevators and automatic doors, and manage the tasks of each robot. Because AGVs require a fixed, guided path and a greater amount of space in which to navigate, they simply aren’t a good choice for many factories and warehouses, which require operational efficiency and flexibility. Since warehouses are often crowded and have narrow aisles, an AMR is better suited to the materials handling industry. Converting an existing AGV into an AMR allows it to become more flexible and productive. It also costs less than purchasing a new AMR, and converting the AGV will typically cost only 40%-50% of its original cost.

How the materials handling industry benefits from robotization

As previously mentioned, robotization offers benefits to many industries, but the materials handling environment stands to be among the industries that benefit the most. Because the warehouse environment itself has a high rate of on-the-job injuries, with nearly 65,000 reported incidents in 2020 alone, automation and robotization are being embraced as one solution to reduce the number of injuries. But that’s not the only reason the materials handling industry is turning to robotization; here are seven ways that it’s beneficial.

1. Improved productivity. Human workers have good days and bad days; they’re also more productive at different times of the day — research shows that productivity drops after lunch and is also lower at the end of the week than at the beginning. AMRs deliver consistent productivity and can deliver the same output at 8 p.m. as they did at 8 a.m.

2. Greater efficiency. Not only do AMRs boost productivity within the warehouse environment, but they’re also more efficient. In a single programmed route, they can transport a greater number (and weight) of materials, dropping them off where needed and streamlining the process for getting materials where they need to be — faster. Because they’re equipped with sensors and controlled by the fleet management system (FMS), there aren’t issues with “traffic jams” within the warehouse or collisions with obstacles, other vehicles or workers. This increased speed and efficiency allows skilled warehouse workers to do their work more efficiently, too — which makes for happier, more productive workers.

3. Reduced costs. Hiring and training new employees is costly; it also may require expenses such as uniforms and safety equipment. When using an AMR, there’s no additional HR costs for hiring and training; it also eliminates the cost of such employee-related expenses as insurance, vacation, workman’s comp and more.

4. Enhanced safety. This benefit is one that cannot be overemphasized. At a time when workers have their choice of jobs and the workforce is shrinking due to retirement and other ongoing factors, the employers who will attract and retain employees are those who can provide a safe and pleasant work environment. Robotization helps create that environment by reducing boredom on the job and promoting efficiency, but the ability to ensure a safer working environment is a bonus that is worth investing in.

5. Fewer errors. Errors can be costly to a company, resulting in lost customers and damaged reputations. Errors can come in many forms, from picking up and delivering the wrong materials to dropping, spilling or breaking products. When humans are assigned repetitive tasks, they lose their concentration, feel tired more easily and are more prone to making mistakes. Using an AMR for “mindless” or repetitive tasks can play a significant role in reducing such errors

6. Easy to implement. Robotization of existing equipment makes work processes easier, and it doesn’t require extensive training or experience programming robots. Because the process is scalable, companies can start with one or two pieces of equipment, then continue robotizing other equipment over time as budgets allow.

7. Adaptable to changing environments. When layouts of a warehouse change due to growth or seasonal needs, an AMR simply needs to be remapped or partially mapped. That’s not the case for AGVs, which follow a set path. This adaptability means that an AMR can grow with the needs of a warehouse — not hinder it.

Is robotization right for your environment?

Robotization packages can help transform your existing warehouse into a safer, more efficient and more productive workplace. It can greatly reduce costs while also addressing some of the complications created by the ongoing worker shortage. To learn more about YUJIN’s robotization solutions and how it can work in your environment, And be sure to download our Materials Handling White Paper.