It’s an enduring image from Star Wars movies: human workers calmly going about their business while their robot coworkers scurry past. Times have changed, and what used to be mind-blowing science fiction is now humdrum reality in many workplaces.

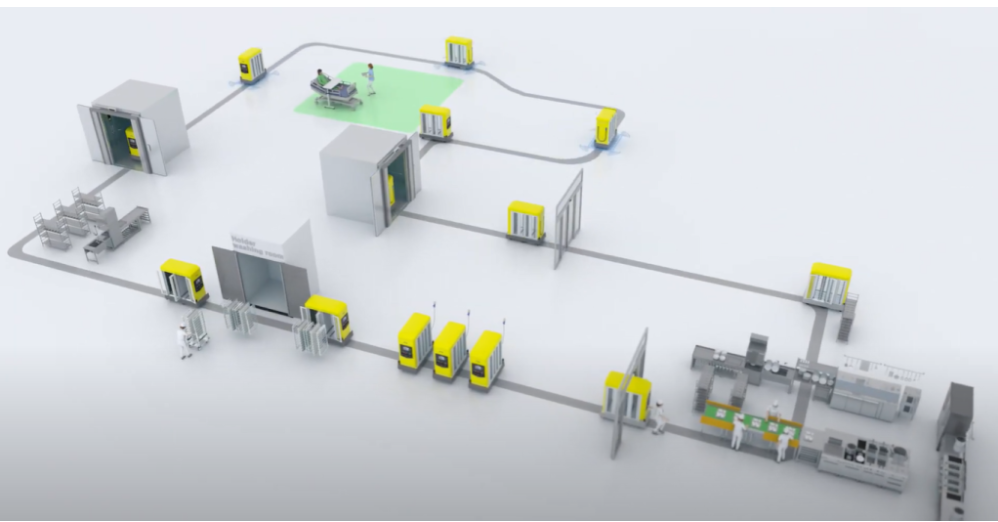

Autonomous Mobile Robots work alongside humans every day in factories, hospitals and even grocery stores. They perform necessary, repetitive tasks like cleaning floors, delivering medicine and taking inventory. It is in warehouses, however, where AMR’s truly shine.

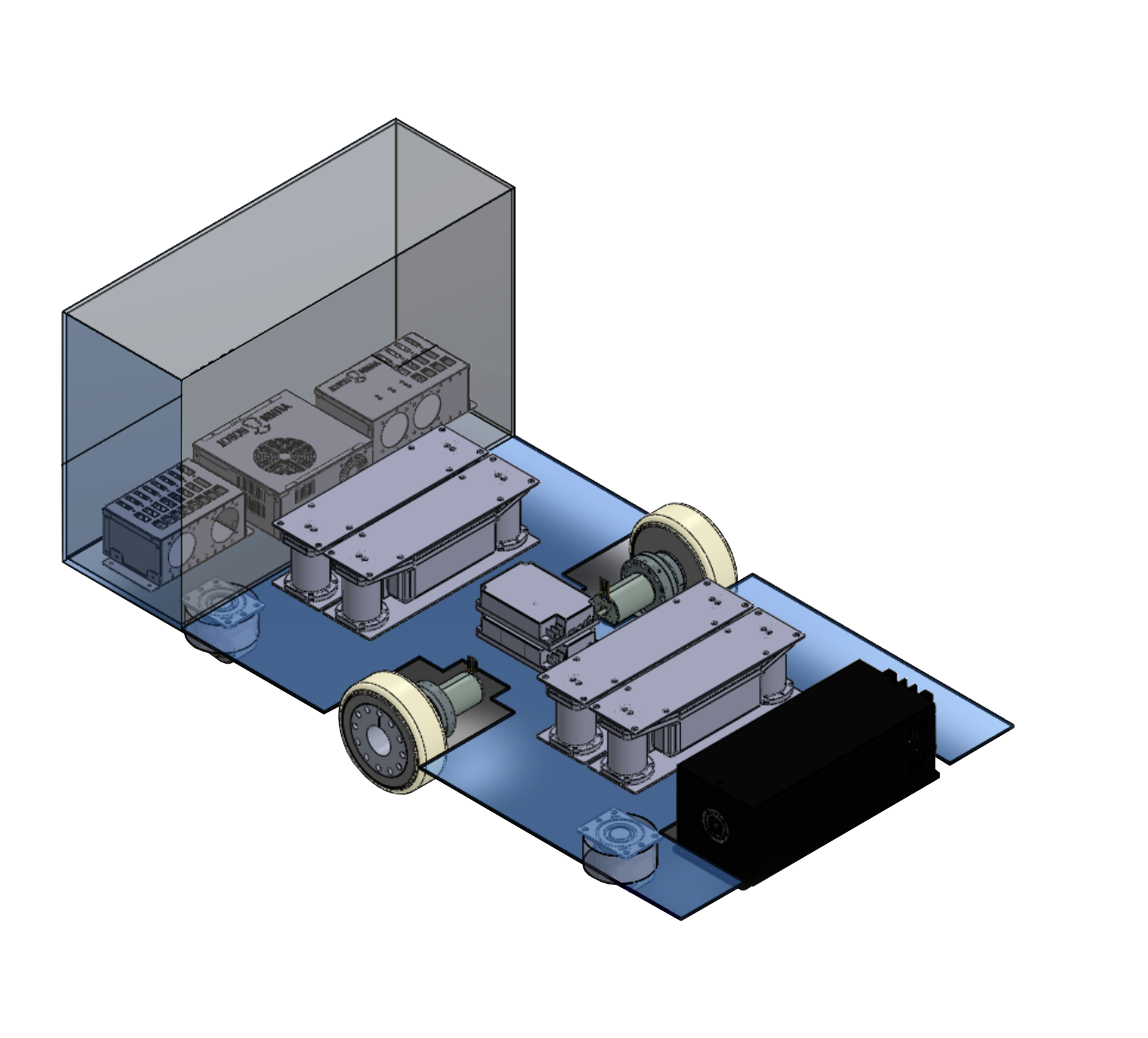

Some Autonomous Mobile Robots can be used to carry items from one place to another. These mechanical couriers are more than souped-up pushcarts. Simultaneous Localization and Mapping (SLAM), technology allows them to know where they are and remember where they’ve been. Instead of following a simple, predetermined path, this mobile robotic carts can navigate to their destination while avoiding obstacles and communicating with automated doors, elevators and each other.

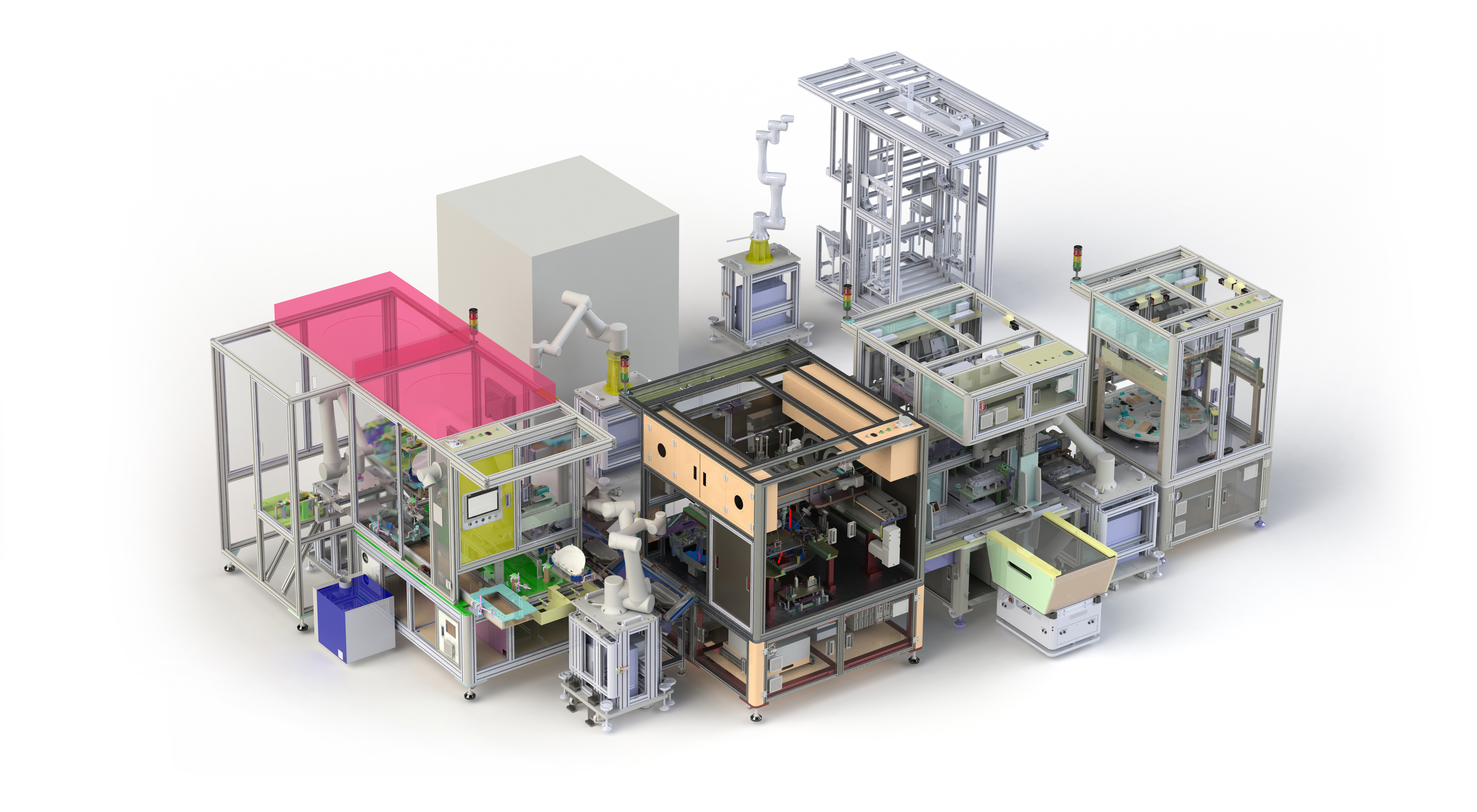

In addition to doing the arduous work of carrying products from place to place, robotic carts serve a number of functions that increase productivity. Thinking of a Mobile Robot simply as a substitute for human labor is like thinking of an automobile as a replacement for a bicycle. With the right strategy and purpose, the machinery adds value beyond the obvious.

Mobile Robots ease holiday stress.

Major retail holidays such as Christmas also tend to be common vacation periods. Warehouse managers face the pressure of increased order volume just as workers want time off to spend with their families. Even a fully staffed warehouse can struggle under an immediate spike in workload because it’s staffed for normal volume.

Human workers are… well, human, so we tend to make more errors as pressure and workloads increase. Autonomous Mobile Robots perform repetitive tasks with a high degree of accuracy and don’t feel pressure. They don’t realize they’re expected to perform at a higher level; they just do it.

Autonomous Mobile Robots don’t ask for vacation days. They don’t pull a muscle lifting a box. They don’t catch the flu during winter months. With a proper Fleet Management System, a warehouse’s robot workforce continues reliably picking inventory and processing orders during the busiest of seasons.

Mobile Robots reduce injuries.

Injuries are part of warehouse life. A tired worker forgets to lift with his legs and strains his back. Another drops a heavy box on her foot. Somebody trips over a discarded box carelessly left in a walkway, or collides with a coworker.

A well-managed fleet of Mobile Robots greatly reduces the risk of these injuries. Mobile Robots handle payloads of varying sizes but have no muscles to strain or bones to break. Their onboard sensors recognize obstacles and moving objects so they can avoid collisions. A good Fleet Management System keeps track of each robot and routes it away from trouble, protecting products from damage and human coworkers from injury.

Robots free humans for important tasks.

Human workers provide value in addition to simple labor. They can make decisions, recognize discrepancies and solve problems. Robots, on the other hand, excel at necessary but repetitive tasks. They can carry 100 loads per day as easily as one load per day. When Mobile Robots perform these jobs, your human staff can focus on more complex matters. Free your workforce for jobs better suited to humans, such as managing inventory, performing inspections and monitoring quality control.

Use warehouse space more efficiently.

With the ecommerce boom, warehouse space is at a premium. Autonomous Mobile Robots reduce the need for additional warehouse space. Narrow aisles and tight spaces present problems to injury-prone workers but are easily navigated by Mobile Robots such as Yujin Robot’s GoCart series. With a strategically planned, well-managed fleet of Mobile Robots, a warehouse can be configured to maximize storage and reduce wasted space without increasing the risk of injury.

Mobile Robots are an increasingly vital part of a warehouse, and their value extends beyond moving materials. With the right robotic cart strategy, a warehouse can store and ship more products and improve conditions for human workers.

These robots don’t have the personality of R2D2 or C3P0, but they do offer a lot more value to your business.