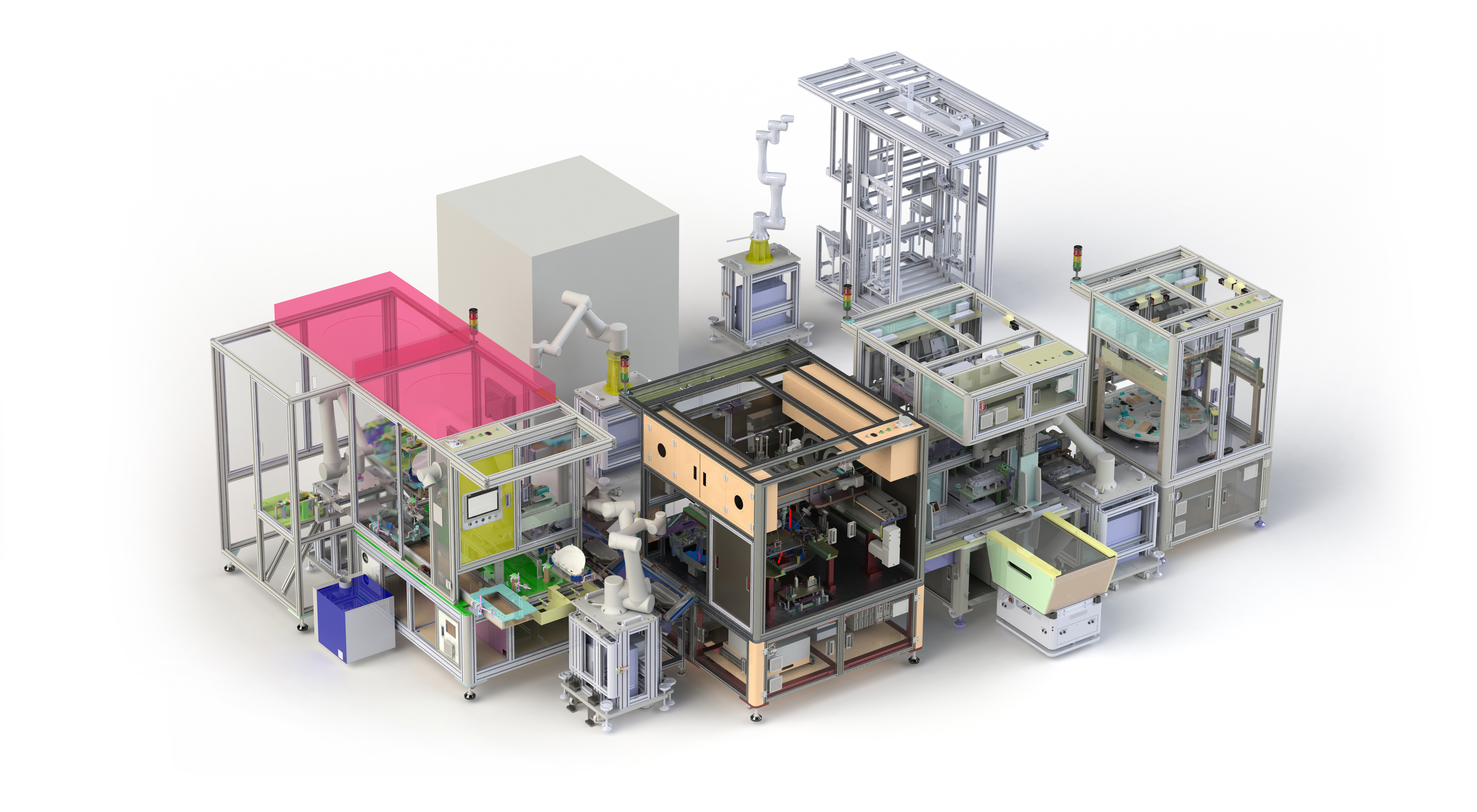

If you’ve made the decision to introduce autonomous mobile robots to your facility, you likely did so because you recognized the many benefits a fleet of AMRs can provide. For starters, they’re more efficient and flexible than a conveyor belt system. They’re designed to handle repetitive tasks with accuracy and speed, freeing human workers for more skilled tasks. And what’s more, a solid fleet of AMRs reduces the risk and cost of workplace injury — and increases output while boosting profit margins and productivity.

Of course, you can’t simply unleash a fleet of mobile robots to roam at will around your warehouse. A group of mobile robots operating independently could quickly become a nightmare of congestion, duplication, and wasted energy.

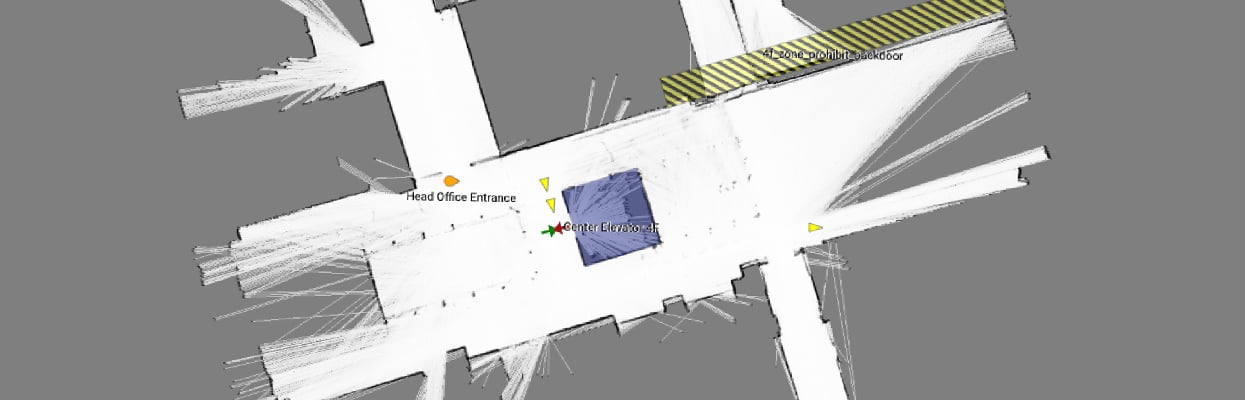

Picture a traffic jam of robots, all trying to access the same aisle in your warehouse, or trying to squeeze into an elevator that’s not big enough. Instead of human workers steadily picking products and fulfilling orders, you find yourself with a fleet of angry robots, unable to get from place to place.

Similarly, you probably don’t want to employ humans to sit at a desk, joystick in hand, and control every movement of every robot. Instead, you want the mobile robots in your fleet to do what is needed, when it’s needed. You need each machine operating at its most efficient capacity. You need to avoid downtime caused by an entire fleet charging or undergoing maintenance at the same time.

You need a fleet management system (FMS).

What Is a Fleet Management System?

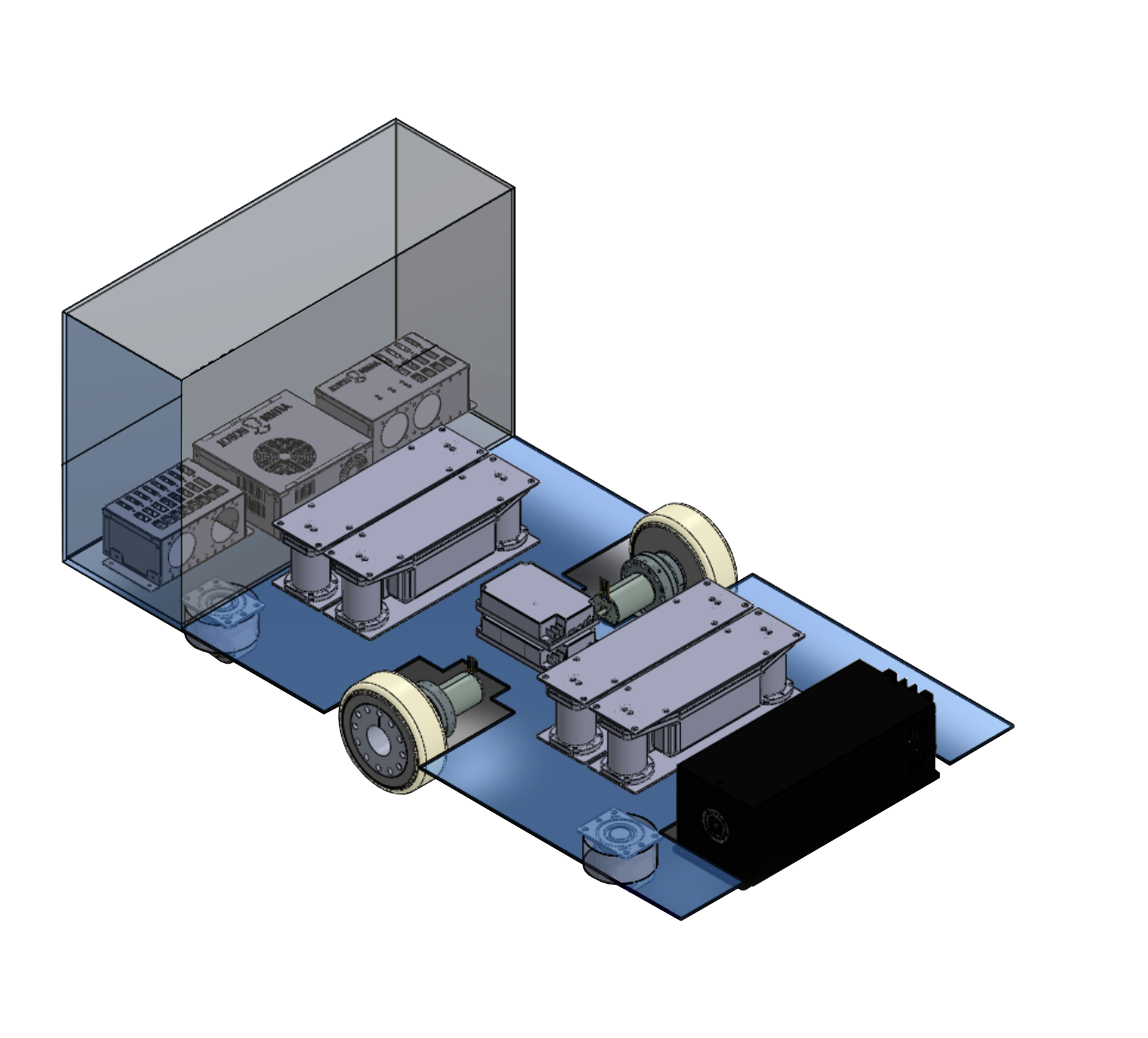

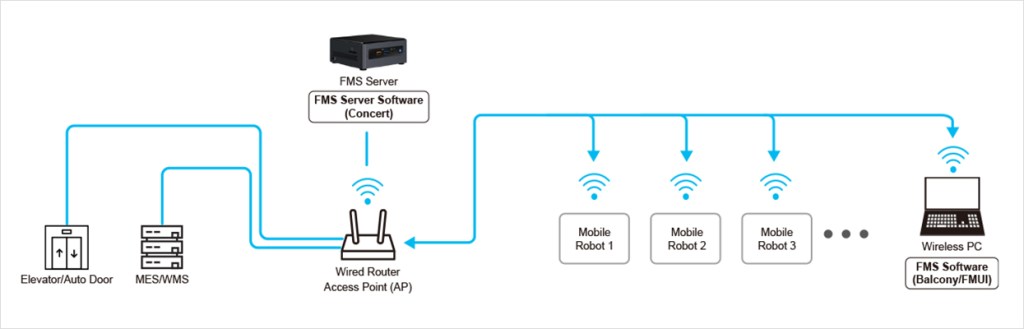

A fleet management system is an intelligent system for mobile robot management, controlling every robot in your network to maintain smooth operation and get the most from each machine. Each robot is directed to the most necessary, productive task it can perform, or it’s parked and charging until needed.

When your fleet of robots is controlled by an intelligent management system, each robot is assigned the most appropriate task at any given moment. Assignments can be changed instantly based on new information, with your FMS constantly evaluating data from each unit.

Just as many large facilities stagger worker shifts and break times so that production lines are always moving, your fleet management system will balance charging times, giving you the greatest possible number of autonomous robots available at any given time.

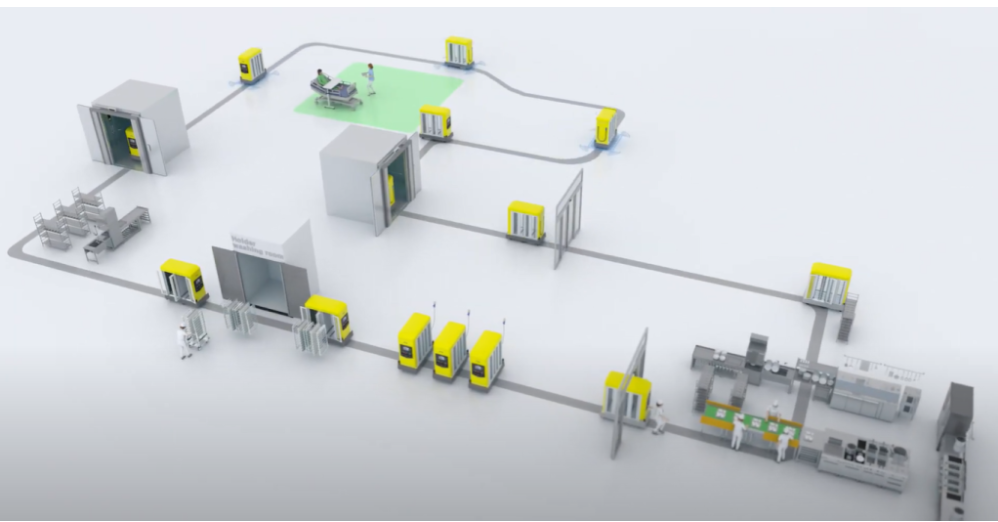

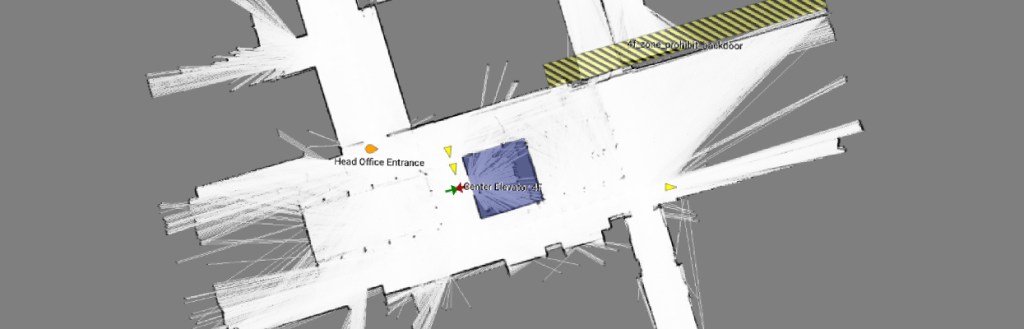

Fleet management systems do more than simply manage traffic in one warehouse or factory. Your FMS can interface with doors and elevators, allowing mobile robots such as Yujin Robot’s Autonomous Mobile Robot GoCart series to carry items from one building to another, or from floor to floor. A fleet management system can direct robots to deliver medication from the pharmacy to a nurse’s station on another floor — or in another building — and return.

Autonomous mobile robots have enabled rapid growth in eCommerce, manufacturing and shipping by putting intelligent systems in charge of large fleets. Fleet management systems are not optional; they’re a requirement for a facility using mobile robots efficiently and productively.