Automated Guided Vehicles (AGV), have been common in warehouses and industrial facilities for some time. These electronic workhorses excel at the simple repetition of moving material or product from one place to another on a regular fixed route, freeing human workers for more complicated tasks.

Manufacturers of these Automated Guided Vehicles have a potent challenger: Autonomous Mobile Robots (AMRs). AGVs use sensors, magnetic strips or wires to follow a set path, without deviation. Their limited on-board intelligence means they can only follow simple programmed instructions.

An AMR, on the other hand, can make decisions in a way that an AGV cannot. With a constant flow of data from onboard cameras and sensors, Autonomous Mobile Robots can identify and maneuver around obstacles, and find the most efficient route to its destination.

If an Automated Guided Vehicle finds an obstacle in its path, the AGV lacks the ability to change direction. It’s not uncommon for a busy warehouse to experience a traffic jam, with several AGVs lined up behind another, each waiting its turn. In addition, QR codes and magnetic strips, which are used as markers, can be easily damaged requiring frequent maintenance.

You need a fleet management The solution is SLAM robotics technology, along with a fleet management system and on-board navigation.

SLAM and Automated Guided Vehicles

Simultaneous Localization and Mapping, or SLAM, offers a helping hand to AGV manufacturers. With SLAM robotics technology, these companies can produce advanced Automated Guided Vehicles that read and react to their surroundings.

Simultaneous Localization and Mapping doesn’t refer to a specific piece of software or technology, but to a system’s ability to map its environment in real time and remain aware of its location in relation to that mapping.

SLAM enables an advanced AGV to explore away from a simple, predetermined path, and to function more independently and efficiently. A SLAM-enabled, Automated Guided Vehicle isn’t restricted to following guidelines on the floor and moving in a predetermined direction. Because of this flexibility and efficiency, SLAM technology exists in a wide variety of autonomous vehicles, from Autonomous Mobile Robots to unmanned aerial vehicles to robotic vacuum cleaners.

Localization and Mapping are an important part of the solution for AGV manufacturers; the rest is navigation. It’s one thing for a robot to know where it is and what’s nearby, but it’s another for it to efficiently navigate in a crowded environment.

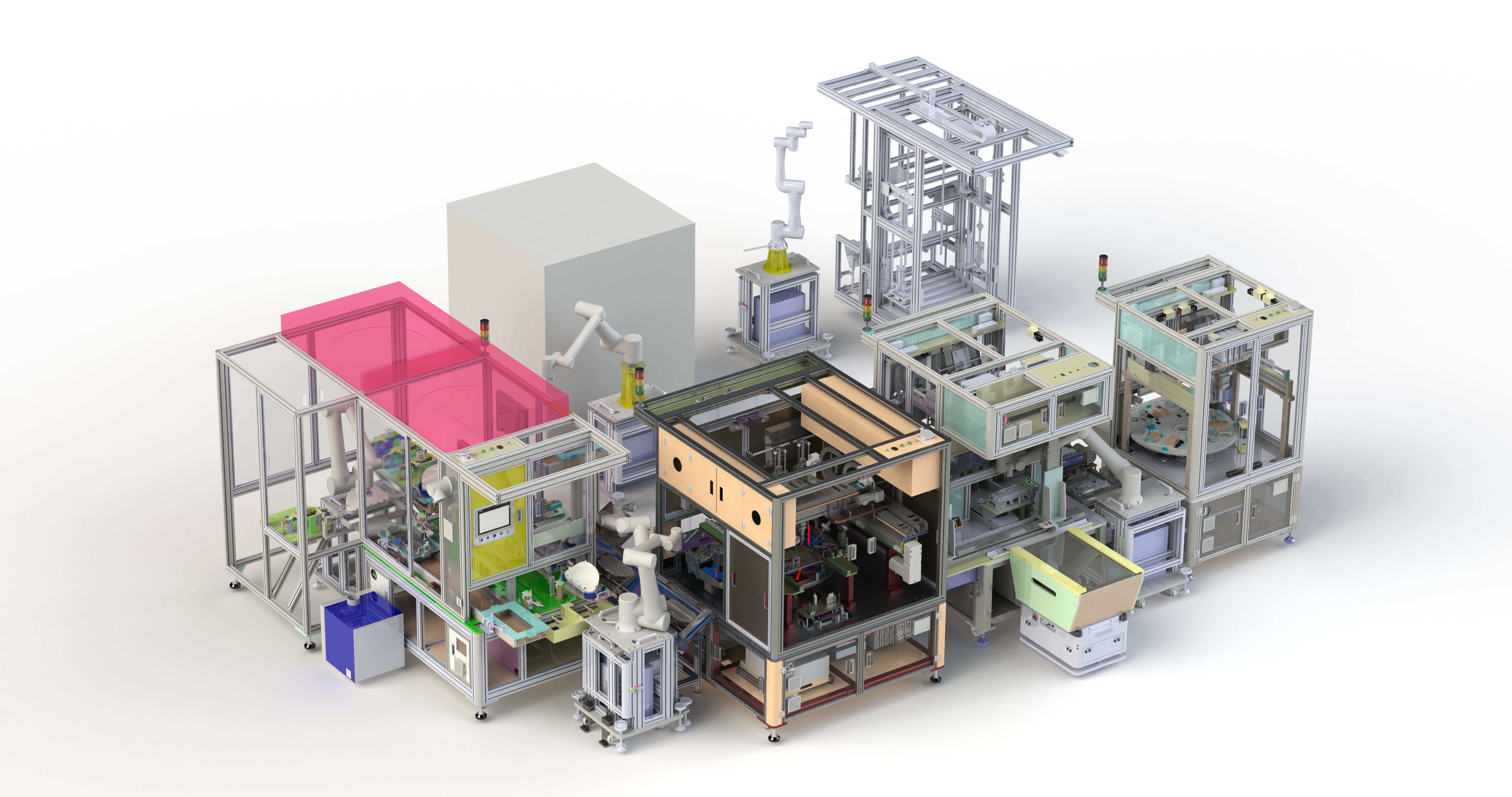

AGV manufacturers benefit from a combined SLAM and navigation system, such as that provided by Yujin Robot. Yujin works closely with manufacturers such as Hantech and BH Systems to produce advanced AGVs and AMRs equipped with Yujin’s AMS-SLAM & Navigation solution.

Yujin’s AMS-SLAM & Navigation works with popular LiDAR sensors to help an AGV generate accurate maps in challenging environments, maintain awareness of its location and move efficiently to its destination.

When your fleet of robots is controlled by an intelligent management system, each robot is assigned the most appropriate task at any given moment. Assignments can be changed instantly based on new information, with your FMS constantly evaluating data from each unit.

Just as many large facilities stagger worker shifts and break times so that production lines are always moving, your fleet management system will balance charging times, giving you the greatest possible number of autonomous robots available at any given time.

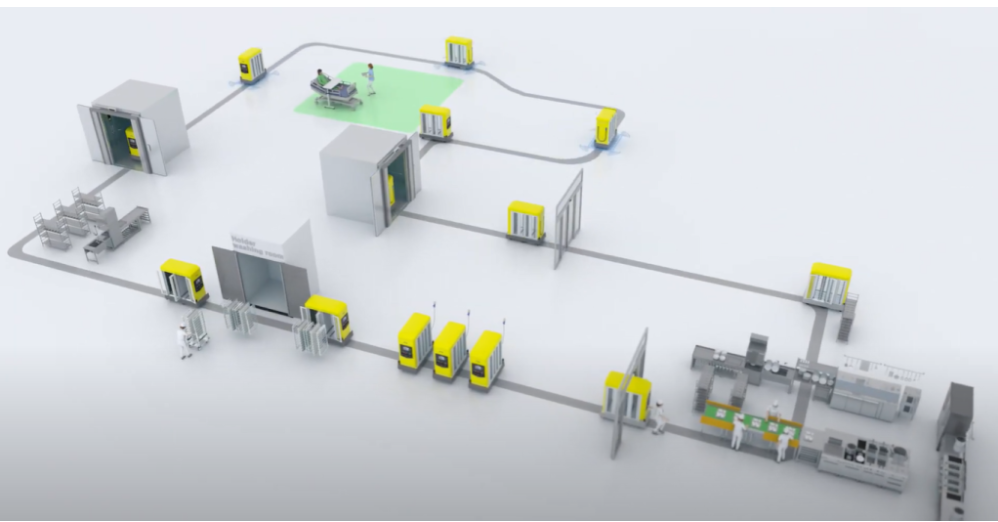

Fleet management systems do more than simply manage traffic in one warehouse or factory. Your FMS can interface with doors and elevators, allowing mobile robots such as Yujin Robot’s Autonomous Mobile Robot GoCart series to carry items from one building to another, or from floor to floor. A fleet management system can direct robots to deliver medication from the pharmacy to a nurse’s station on another floor — or in another building — and return.

Autonomous mobile robots have enabled rapid growth in eCommerce, manufacturing and shipping by putting intelligent systems in charge of large fleets. Fleet management systems are not optional; they’re a requirement for a facility using mobile robots efficiently and productively.